Automatic High Speed Gluing Machine 850/1100 4 &6 Corner Box Folding Gluing Machine Paper Box Folder Gluer Machine

Company Introduction

Wenzhou Weston Print and Pack Machinery CO., LTD is a professional manufacturer for post-press equipment, mainly produce flute laminating machine, folder gluer and bopp film laminating machine, etc. WESTON Machinery with the development for more than 20 years, we become a high-tech enterprise. Our products have got CE certificate. We supply qualified equipment, effective and convenient solutions for cardboard box and corrugated box folding industry. We will be continuously providing higher quality and satisfying services in return for the support and favors of our customers.

Specification & Box Size

| Model | GSF-850C4&6 | GSF-1100C4&6 |

| Paper Thickness | 200-800gsm paperboard,ABCEF

Corrugated boxes |

200-800gsm paperboard,ABCEF

Corrugated boxes |

| Box Type | Standard box, double sides, lock bottom box, flat mouth box. | Standard box, double sides, lock bottom box, flat mouth box. |

| Max Speed | 400m/min | 400m/min |

| Power | 32KW | 32KW |

| Weight | 7000KGS | 7500KGS |

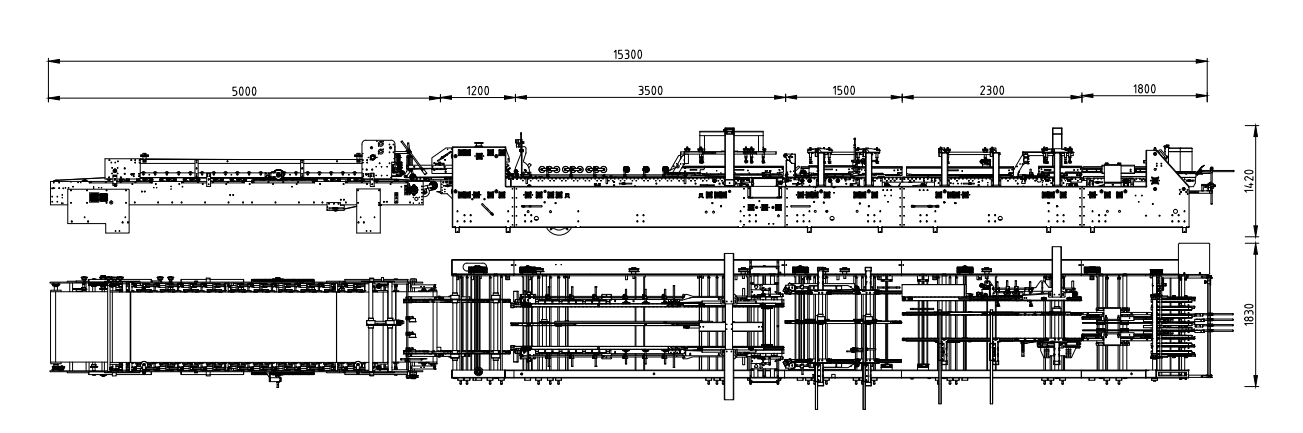

| Size | 15.3*1.83*1.42m | 15.3*2.3*1.42m |

| (C.A,P): | 6pa | 6par |

| (C.A.E) | 6/h | 6/h |

| (C.A.V): | 40L | 40L |

| FOB NINGBO Standard Machine with 3 spary Gun | USD | USD |

Main features & machine configuration

·Humanized design,a hexagonal wrench can adjust most of the parts,debugging easy;

·Touch Screen, button, remote control distance, three panels of the trinity are operating equipment. Convenient and quickly.

·The machine wallboard and some complex casting using computer laser cutting, dominant board conditioning treatment after hot and cold.

·Parts design, processing precision, good stability, high speed low noise, good durability.

·Bearing adopts Japan NSK bearing, the main shaft adopts hard chrome steel rods, fastening bolt use 1.9 on the richer scale.

·Main motor adopt Taiwan TECO brand, pressing machine adopt Taiwan SHENG BOND precision CPG brand.

·Master electrical frequency converter, PLC. Schneider Brand, the higher WEINVIEW touch screen TAIWAN BRAND.

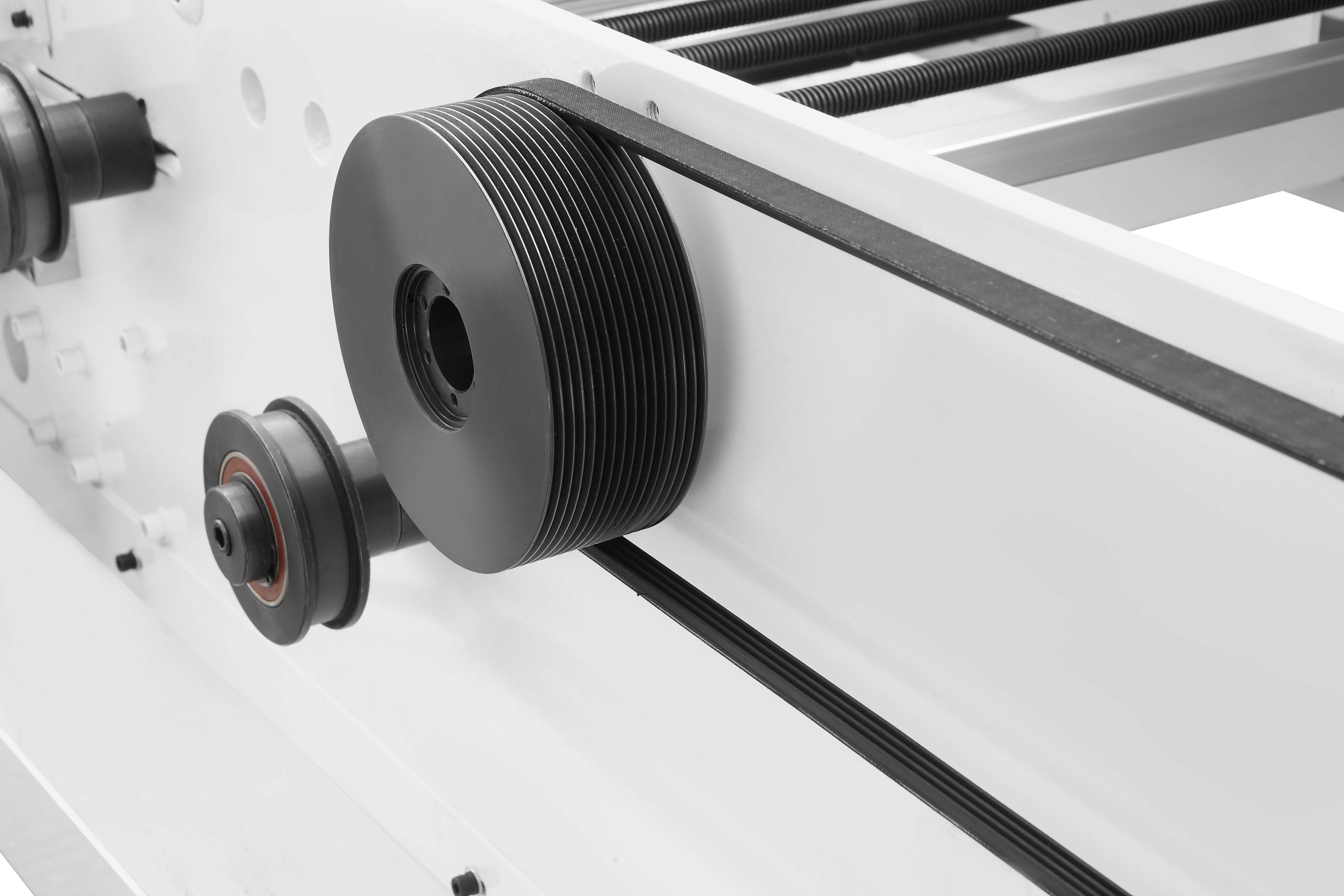

·Wedge pulleys and wedge belt adopts FRENCH Hutchinson Brand.Conveyor belt by Swiss RAPPLON, Flat belt adopt Japan NITTA belt.

Composition& module

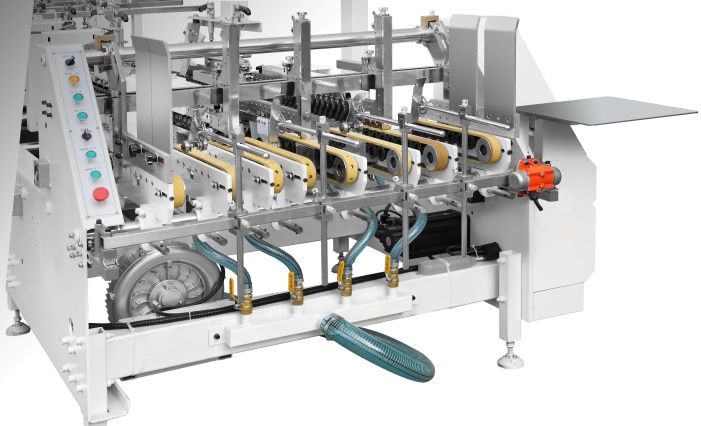

Feeder Section

·Independent servo motor drive, high speed operation Is accurate transfer paper, so as to achieve the best capacity;

·Large micro adjust paper knife, lateral baffle width adjustment is convenient;

·Vortex pump configuration Independent suction chamber and the valve, increase rubber belt paper friction with smooth paper;

·Scalable paper stack at the back of the support for longer box.

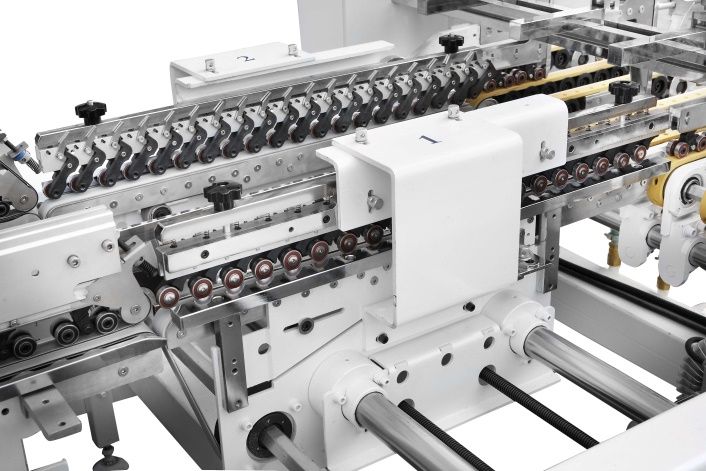

Paper Alignment System

· Independently adjustable side gauge, paper work on a transverse stretching device and delivery by a parallel guide Bracket, ensure paper parallel alignment;

·Both sides can realize alignment function from the device, the operation Is simple rapid

Pre-folding Section

·The upper left glue flap 180° pre-folding, the third line 135° pre-folding;

·The First and the third line folding open the device

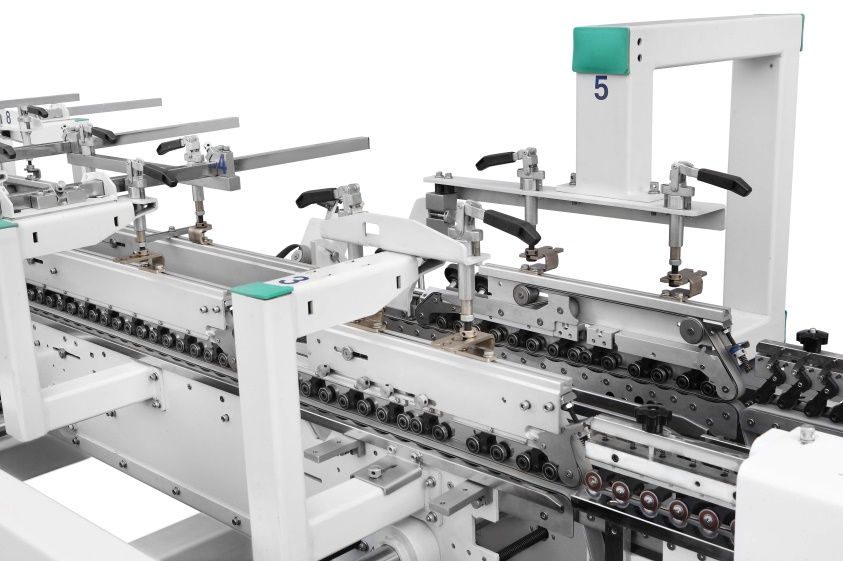

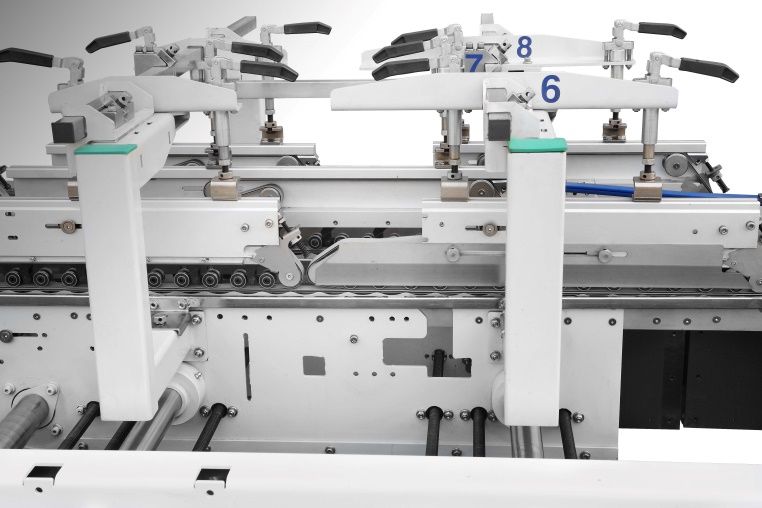

4&6 Corner Module

Intelligent electronic hook system, servo motor drive control can adjust the direction of movement of folding hook to adapt the length of folding,complete folding back on peg , lock bottom and other special folding function at the same time. These can meet the requirement of a variety of different box.

Lock-bottom Section

·Equipped with bottom combination adjustment mechanism, ideal design and easy operation,high stiffness spring hook to ensure accurate action;

·Adjustable hook device, modular design, significantly reduced the transform box type of set-up time, convenient Installation and transformation of attachment;

·Configuration and high elastic hook module;

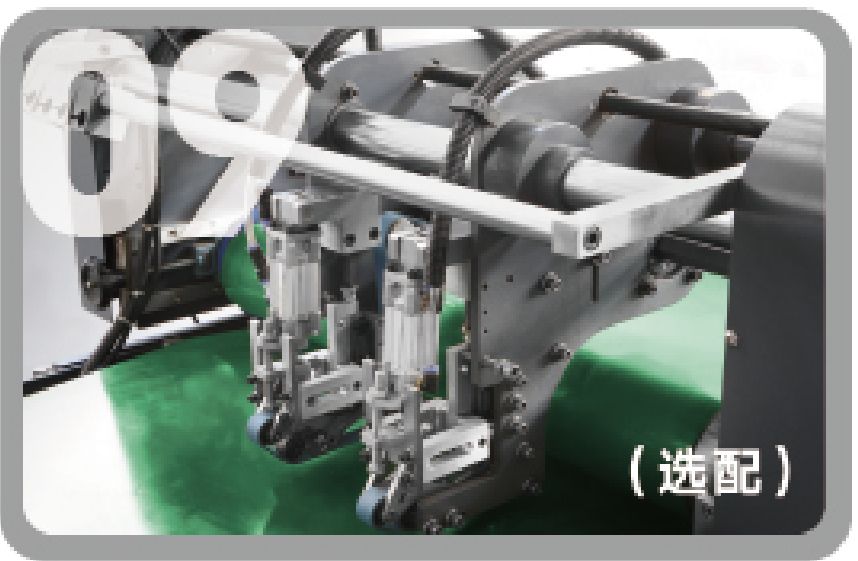

(Gluing Tank Module)

·Paste on the drum using electronic spray adhesive system, according to the model select configuration with two or three sets of cold glue guns;

·Other top electronic spray adhesive system configuration can choose according to the needs of aircraft configuration;

·Cylinder for each side of the paste, a large capacity design, do not jilt or leak glue during high-speed working.

Folding Section

·Accurately completing the second line, the fourth line 180 degrees combination; Around 180 degrees abduction Angle Is adjustable, with a belt transmission devIC8, which can effectively ensure the parallel alignment, folding carton samp1e accurately closed;

·Two sets of bracket and the bracket, the conveyor belt width is 25 mm, the conveyor belt Width & 34 mm, 25 mm kidnapper broadband 34 mm l 40 mm 1 50 mm;

·Equipped with the belt tension automatic control system, easy to tear open outfit;

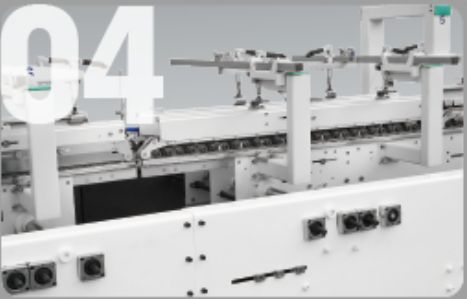

Transfer Section

·On two sets of bracket and the bracket, the belt width is 25 mm is equipped with the belt tension automatic control system, easy to tear open outfit;

·Automatic tracking count, kicking, Insert paper automatically detect outage alarm;

·According to the model and box type lock bottom box module; Continuous automatic produce box and transfer box.

Optional

The Front-end of conveyor section is equipped with pneumatic box module, driven by pneumatic with photoelectric, two sets of belt bracket interactive action, ensure the carton perfect accumulation;

Back stacking corrector, reset the carton position, to ensure the carton into the conveyor section more smoothly.

4 and 6-corner device

Machine using motorized and united electronic back folding system with intelligent servo motor technology.(brand: Weimiao, China)

Conveyor Section

·Independent motor drive; (follow) manual and automatic operation mode;

·According to the different length of the box, conveyor belt pressure driven by motor, can move, configure automatic correction device; Pressure adjustment with pneumatic system, it is convenient adjustment.

·Throughout the total length of 5,6 meters effectively conveying, available length 3.6 meters, to extend the time of cartons of adhesive, improve the quality of adhesive;

Spraying System (cold glue)

Equipped with three guns, convenient in the production of 4/6 corner box and various special-shaped box, gluing quickly and accurately sizing.

Touch Screen

Servo Correction Device

Wedge Belt Wheel

Remote Control Unit

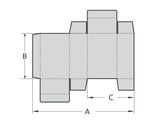

| Common type and sizeCarton type and size: |  |

||

| ModelModel | 850Type | 1100Type | |

| A75-650 | 75-800 | 75-1100 | |

| B60-650 | 60-800 | 60-800 | |

| C(Min)35 | 35 | 35 | |

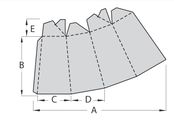

| Size of bottom lock carton |  |

||

| Model650Type | 850Type | 1100Type | |

| A146-650 | 160-800 | 146-1100 | |

| B90-650 | 90-800 | 90-800 | |

| C(Min)20 | 20 | 20 | |

| D(Min)30 | 35 | 35 | |

| E(Min)40 | 20 | 20 | |

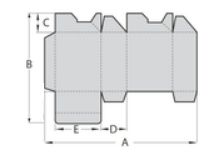

| Carton type |  |

||

| Model650Type | 850Type | 1100Type | |

| A160-650 | 160-800 | 160-1100 | |

| B90-650 | 90-800 | 90-800 | |

| C(Min)40 | 40 | 40 | |

| D(Min)35 | 35 | 35 | |

| E(Min)20 | 20 | 20 | |

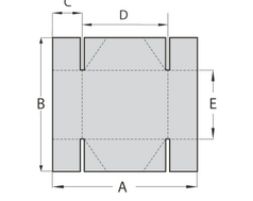

| Size of 4 corners box |  |

||

| Model650Type | 850Type | 1100Type | |

| A160-500 | 160-800 | 160-1100 | |

| B120-650 | 120-800 | 120-800 | |

| C(Min)20-200 | 20-200 | 20-200 | |

| D(Min)90 | 90 | 90 | |

| E(Min)80 | 80 | 80 | |

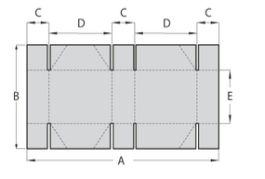

| Size of 6 corners box |  |

||

| Model650Type | 850 Type | 1100 Type | |

| A250-650 | 250-800 | 250-1100 | |

| B120-650 | 120-800 | 120-800 | |

| C(Min)20-200 | 20-200 | 20-200 | |

| D(Min)90 | 90 | 90 | |

| E(Min)80 | 80 | 80 | |

Carton type

Bottom lock carton type

Four corner carton type

Six corner carton type

Technical data

Plasma System is Optional

Plasma 3 gun ( Optional) USD 5000.00

Box folding-gluing bonding in the industry of print and package.

The activation application to bonding surface of atmospheric pressure plasma processing technology process.

In order to put an end to the degumming phenomenon at the gluing position of the paper box, the use of plasma treatment can improve the bonding fastness of gluing position of UV, coated plastic and folding paper box and makes them never come to degumming , which greatly reduces the cost of rework.The processing operated by plasma technology can use ordinary environmental water binder to reduce the use of glue and effectively reduce the cost of production.Plasma equipment can be directly installed in the full automatic box folding-gluing machine with online processing and does not affect the existing process.

The polishing and gluing method of plasma instead of mechanical eliminates the pollution of paper powder and paper wool to the production environment.

Drawing

| Electric Components List For Folder Gluer | ||||

| ID | Name | Specification | Quantity | Brand |

| 1 | Mainframe | TM218LDA40DRPHN | 1 | Schneider Electric SA |

| 2 | Touch Screen | TK60701 | 1 | Vaillant Germany |

| 3 | Servo Motor | EPS-TA0305123+130DNMA1-03D0AAM 3Kw 15NM | 1 | DORAN China |

| 4 | Frequency Converter | AVT310HU22N4 3PH 380V 2.2Kw | 2 | Schneider Electric SA |

| 5 | Frequency Converter | AVT310HU75N4 3PH 380V 7.5Kw | 1 | Schneider Electric SA |

| 6 | Power Filter | AN-20B22JB | 1 | Shanghai China |

| 7 | Power Switch | S-24-100(24V 100W) | 1 | Mingwei China |

| 8 | Air Switch | NSC100B3050N 50A | 1 | Chint Group |

| 9 | Air Switch | EA9AN3C32 3P/16A(C32N-3P-C16) | 1 | Chint Group |

| 10 | Air Switch | EA9AN3C32 3P/10A(C32N-3P-C10) | 5 | Chint Group |

| 11 | Air Switch | EA9AN2C5 2P/5A(C32N-2P-C5) | 1 | Chint Group |

| 12 | Air Switch | EA9AN1C5 2P/5A(C32N-1P-C5) | 1 | Chint Group |

| 13 | AC Contactor | LC1-E3210M5E | 1 | Schneider Electric SA |

| 14 | AC Contactor | LC1-E1810M5E | 1 | Schneider Electric SA |

| 15 | AC Contactor | LC1-E0910M5E | 4 | Schneider Electric SA |

| 16 | Thermal Overload Relay | LRE14N 7A | 1 | Chint Group |

| 17 | Mainature Intermediate Relay | DV24V PXZE1M2C+RXM2LB2P7 | 6 | Schneider Electric SA |

| 18 | Transformer | BK-500 380V 220V/36V 500W | 1 | Chint Group |

| 19 | Remote Controller | PS11 0FA5 31 AC220V | 1 | Taiwan China |

| 20 | Optoelectronic Switch | E3Z-D61 | 1 | omron |

| 21 | Travel Switch | YBLX-8166 | 1 | Chint Group |

| 22 | Mushroom Button | ZB2BS54C | 3 | Schneider Electric SA |

| 23 | Buzzle | AD16 DC24V | 1 | Schneider Electric SA |

| 24 | Flat Button | ZB2BA3C | 7 | Schneider Electric SA |

| 25 | Flat Button | ZB2BA4C | 2 | Schneider Electric SA |

| 26 | Two Switch-contact | ZB2BD2C | 1 | Schneider Electric SA |

| 27 | Two Reset Switch | ZB2BD3C | 2 | Schneider Electric SA |

| 28 | Aviation Plug | DF4 | 6 | Schneider Electric SA |

| 29 | Aviation Plug | DF6 | 2 | China |

| 30 | Aviation Plug | D16 | 2 | China |

| 31 | Terminal Connector | TB-2505 50A | 1 | China |

| 32 | Terminal Connector | TD-15 16A 40 | 1 | China |