GSF-650 800G Automatic High Speed Corrugated Carton Box Folding Gluing Machine Crash Lock Bottom Folder Gluer

Company Introduction

Wenzhou Weston Print and Pack Machinery CO., LTD is a professional manufacturer for post-press equipment, mainly produce flute laminating machine, folder gluer and bopp film laminating machine, etc. WESTON Machinery with the development for more than 20 years, we become a high-tech enterprise. Our products have got CE certificate. We supply qualified equipment, effective and convenient solutions for cardboard box and corrugated box folding industry. We will be continuously providing higher quality and satisfying services in return for the support and favors of our customers.

Quotation List

| No. | Product | Qty | Unit Price (FOB Ningbo) |

Delivery Time | |

|

GSF-800G |

GSF-650G | ||||

| Automatic Straight Line Folder Gluer machine | 1 Set | 20days | |||

| Automatic Pre-fold +Straight Line Folder Gluer machine | 1 Set | 20days | |||

| Automatic Lock Bottom Folder Gluer machine | 1 Set | 20days | |||

| Automatic Pre-fold & Lock Bottom Folder Gluer machine | 1 Set | 20days | |||

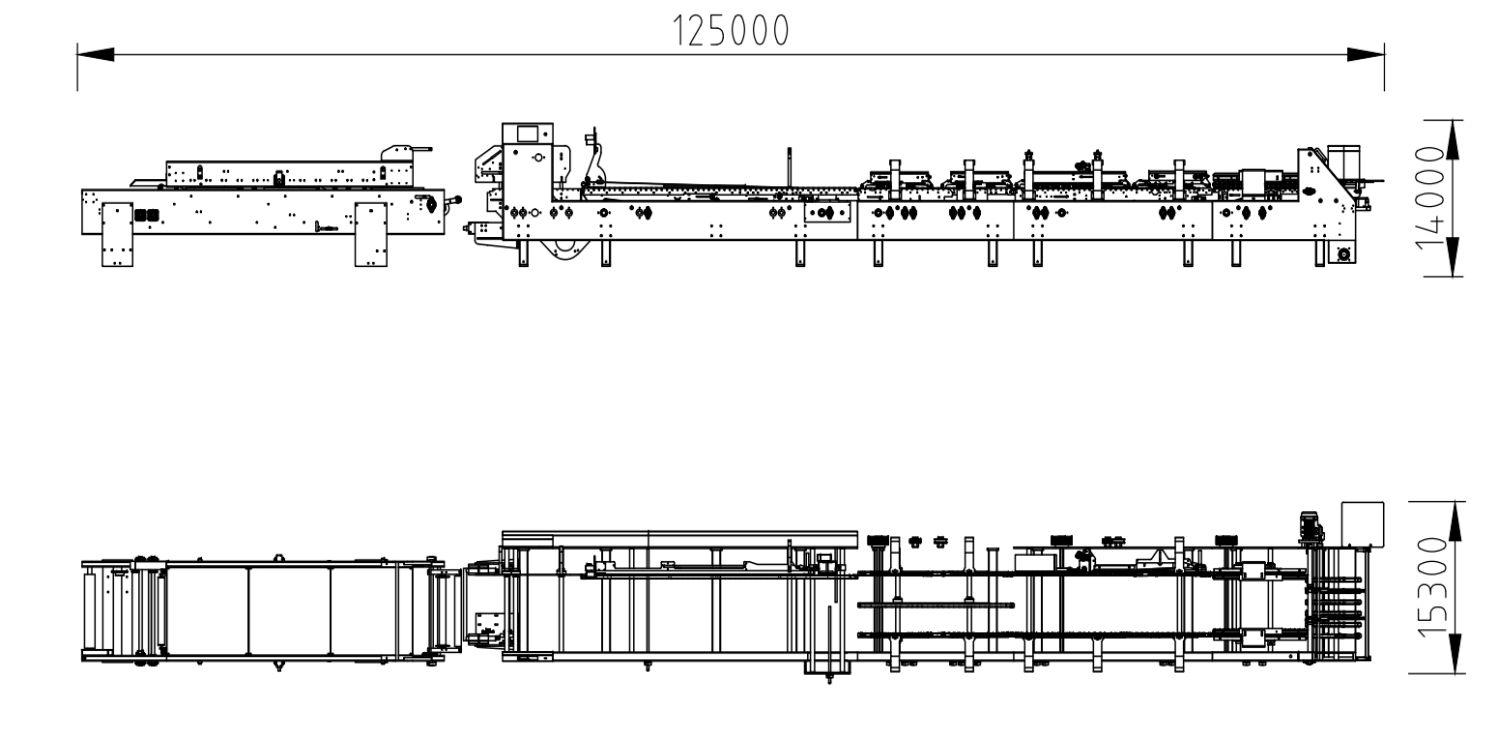

Specification & Box Size

| Model | GSF-650G | GSF-800G | |

| Paper Thickness | 180-800gsm paperboard | 180-800gsm paperboard | |

| Box Type | Standard box, double sides, lock bottom box, flat mouth box. | Standard box, double sides, lock bottom box, flat mouth box. | |

| Paper Width | 650mm | 800mm | |

| Max Speed | 350m/min | 350m/min | |

| Power | 15KW | 17KW | |

| Weight | 5000KGS | 6000KGS | |

| Size | 12.5*1.05*1.5m | 12.5*1.2*1.5m | |

| (C.A,P): | 6par | 6par | |

| (C.A.E) | 6/h | 6/h | |

| (C.A.V): | 40L | 40L |

·Humanized design,a hexagonal wrench can adjust most of the parts,debugging easy;

·Touch Screen, Convenient and quickly set parameter.

·The machine wallboard and some complex casting using computer laser cutting, dominant board conditioning treatment after hot and cold.

·Parts design, processing precision, good stability, high speed low noise, good durability.

Composition& module

Feeder Section

·Independent motor drive, high speed operation Is accurate transfer paper, so as to achieve the best capacity;

·Large micro adjust paper knife, lateral baffle width adjustment is convenient;

·Vortex pump configuration Independent suction chamber and the valve, increase rubber belt paper friction with smooth paper;

·Scalable paper stack at the back of the support for longer box.

Paper Alignment System

· Independently adjustable side gauge, paper work on a transverse stretching device and delivery by a parallel guide Bracket, ensure paper parallel alignment;

·Both sides can realize alignment function from the device, the operation Is simple rapid

Pre-folding Section

·The upper left glue flap 180° pre-folding, the third line 135° pre-folding;

·The First and the third line folding open the device

Lock-bottom Section

·Equipped with bottom combination adjustment mechanism, ideal design and easy operation,high stiffness spring hook to ensure accurate action;

·Adjustable hook device, modular design, significantly reduced the transform box type of set-up time, convenient Installation and transformation of attachment;

·Configuration and high elastic hook module;

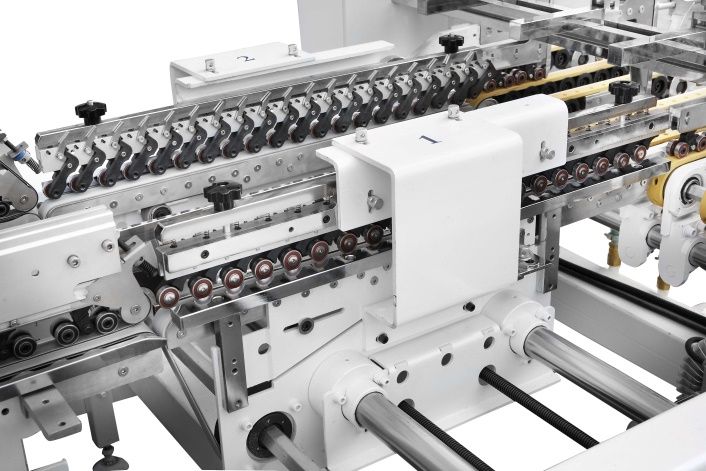

Gluing Tank Module

·Paste on the drum using electronic spray adhesive system, according to the model select configuration with two or three sets of cold glue guns;

·Other top electronic spray adhesive system configuration can choose according to the needs of aircraft configuration;

·Cylinder for each side of the paste, a large capacity design, do not jilt or leak glue during high-speed working.

Folding Section

·Accurately completing the second line, the fourth line 180 degrees combination; Around 180 degrees abduction Angle Is adjustable, with a belt transmission device, which can effectively ensure the parallel alignment, folding carton samp1e accurately closed;

·Two sets of bracket and the bracket, the conveyor belt width is 25 mm, the conveyor belt Width & 34 mm, 25 mm kidnapper bro

adband 34 mm l 40 mm 1 50 mm;

·Equipped with the belt tension automatic control system, easy to tear open outfit;

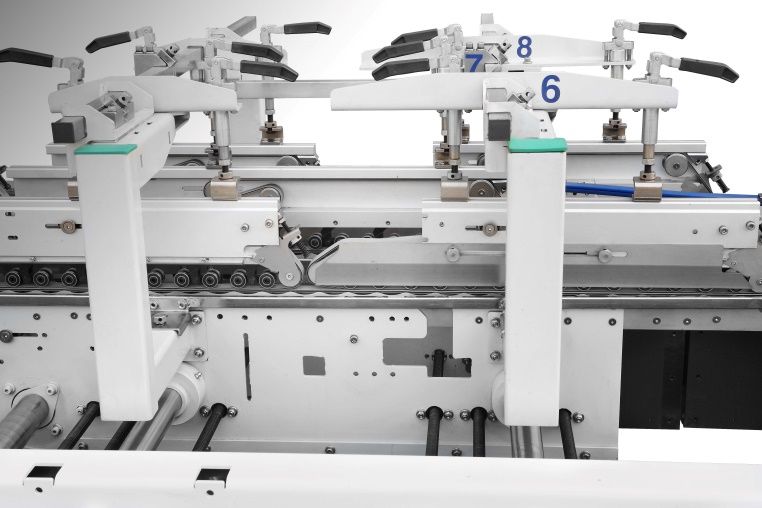

Transfer Section

·On two sets of bracket and the bracket, the belt width is 25 mm is equipped with the belt tension automatic control system, easy to tear open outfit;

·Automatic tracking count, kicking, Insert paper automatically detect outage alarm;

·According to the model and box type lock bottom box module;

Continuous automatic produce box and transfer box

Conveyor Section

·Independent motor drive; (follow) manual and automatic operation mode;

·According to the different length of the box, conveyor belt pressure driven by motor, can move, configure automatic correction device; Pressure adjustment with pneumatic system, it is convenient adjustment.

·Throughout the total length of 5,6 meters effectively conveying, available length 3.6 meters, to extend the time of cartons of adhesive, improve the quality of adhesive;

Spraying System (cold glue)

Equipped with three guns, convenient in the production of 4/6 corner box and various special-shaped box, gluing quickly and accurately sizing.

The multi-ribbed pulley and the multi-ribbed belt

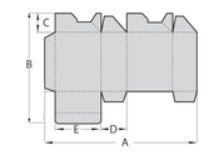

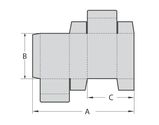

| Common type and sizeCarton type and size: |  |

||

| Model | 650Type | 800Type1100Type

|

|

| A | 75-650 | 75-80075-1100 | |

| B | 60-650 | 60-80060-800 | |

| C(Min) | 35 | 3535 | |

| Size of bottom lock carton |

|

||

| Model | 650Type | 800Type | |

| A | 146-650 | 146-800 | |

| B | 90-650 | 90-800 | |

| C(Min) | 20 | 20 | |

| D(Min) | 30 | 30 | |

| E(Min) | 40 | 40 | |

Technical data

Plasma System is Optional

Box folding-gluing bonding in the industry of print and package

The activation application to bonding surface of atmospheric pressure plasma processing technology process.

In order to put an end to the degumming phenomenon at the gluing position of the paper box, the use of plasma treatment can improve the bonding fastness of gluing position of UV, coated plastic and folding paper box and makes them never come to degumming , which greatly reduces the cost of rework.The processing operated by plasma technology can use ordinary environmental water binder to reduce the use of glue and effectively reduce the cost of production.Plasma equipment can be directly installed in the full automatic box folding-gluing machine with online processing and does not affect the existing process

The polishing and gluing method of plasma instead of mechanical eliminates the pollution of paper powder and paper wool to the production environment.

| (1)Time of Delivery:30-45 days after receiving your advance payment |

| (2)Loading Port & Destination:From NINGBO,CHINA To your port |

| (3)Terms of Payment:30% T/T deposite,70% balance T/T payment before the shipment |

| (4)Quotation Valid time:30 days |

| (5)Warranty:One year free warranty start from waybill date. |

| (6)Overseas service:Engineers are available to oversea service, engineer fee USD 100/days.,buyer support visa, air ticket and accommodation(During Covid-19 will supply online video operation introduction or video call. |