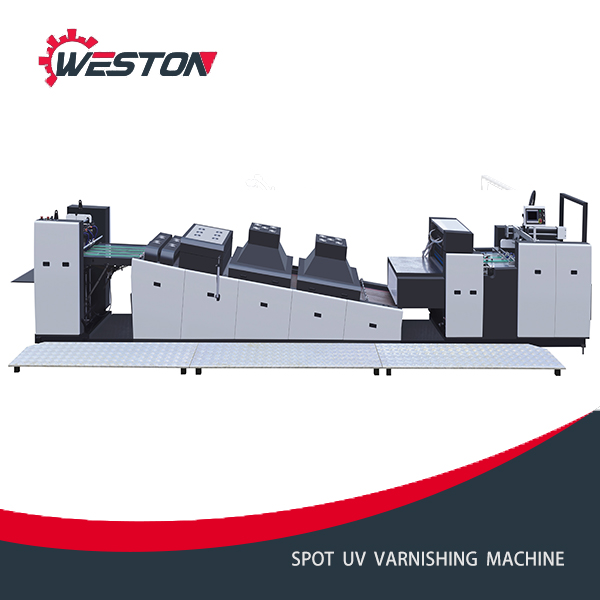

SJUV-800A Fully Automatic Spot UV/ full sheet UV Varnishing Micro Spot UV Varnish Coating Machine

Specifications

| Model | SJUV-800A |

| Max.Sheet Size | 760*585mm |

| Min.Sheet Size | 240*240mm |

| Sheet Weight | 80~400g/m2 |

| Speed | 5~60m/min |

| Power | 47Kw |

| UV Lamp | 3pcsx8Kw |

| IR Lamp | 18pcsx1.2Kw |

| Weight | 75000kg |

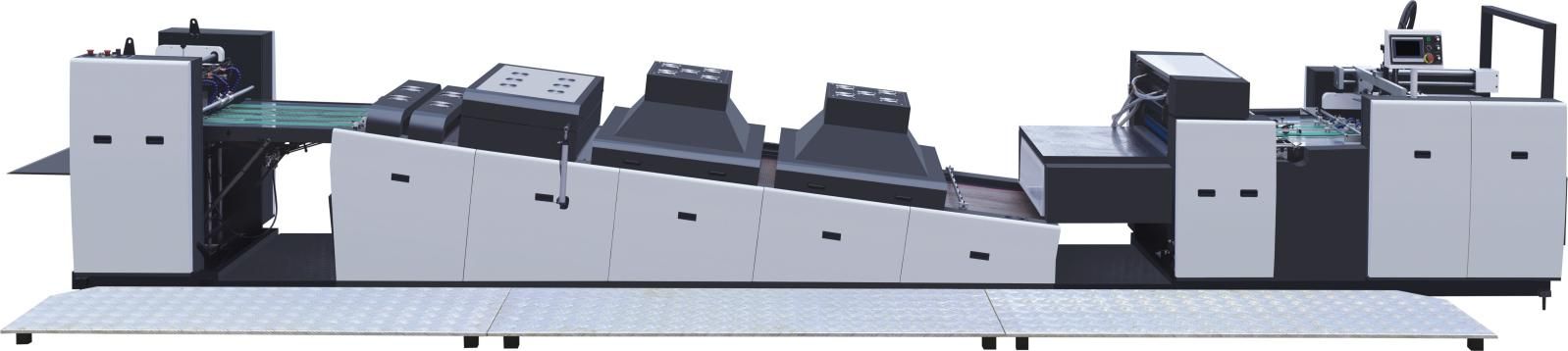

| Dimension | 7800x1420x1730mm |

Machine configuration and technical specification

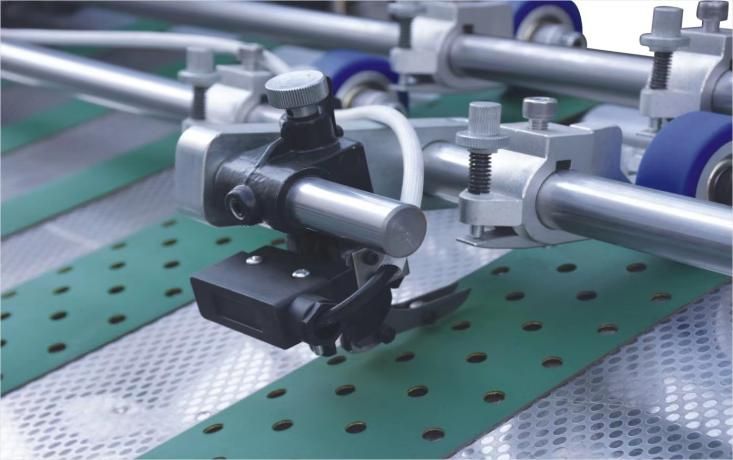

1. Automatic paper feeder

- High reliability is adopted for fast and smooth paper feeding.

- Equipped with sensitive electromechanical double-tension detector and foreign body baffle, the machine will stop immediately if abnormal.

- Accurate and reliable front gauge and side gauge.

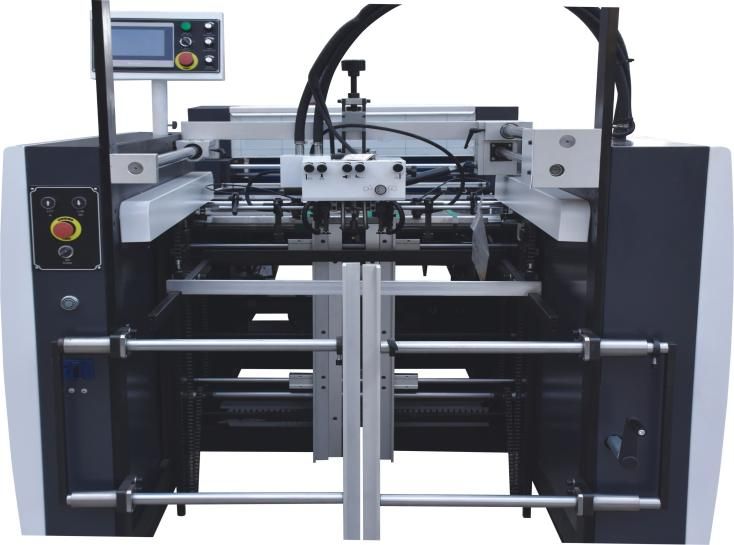

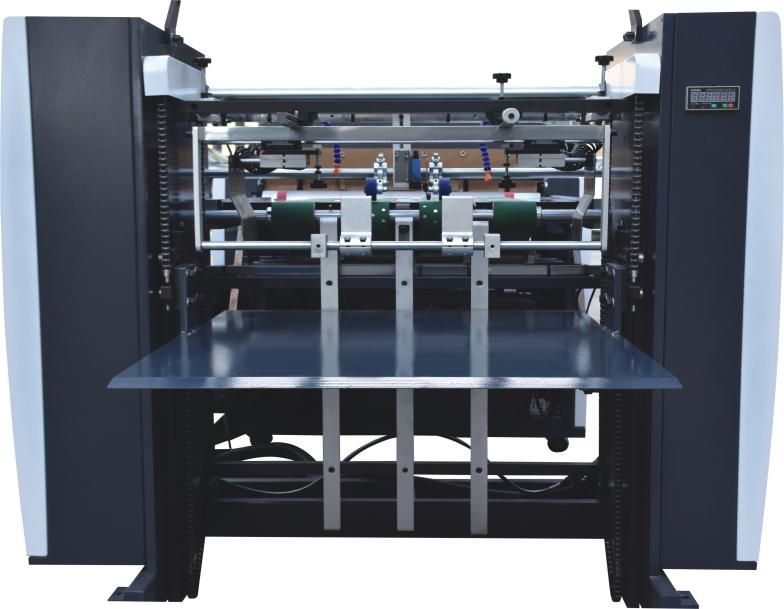

2. Coating host

- Coating speed up to 6000-7500sheets/hour.

- Using a large diameter imprint drum, drum by dynamic balance, coating oil film flat.Double shaft oil transfer, scraper, simple and reliable control of oil.

- Coating drum adopts screw fixed clamping device, which is simple and durable.

- Roller forward and backward oil transfer structure, easy conversion, flexible thickness adjustment.

- Optional ceramic anilox roller and cavity scraper or ordinary scraper.

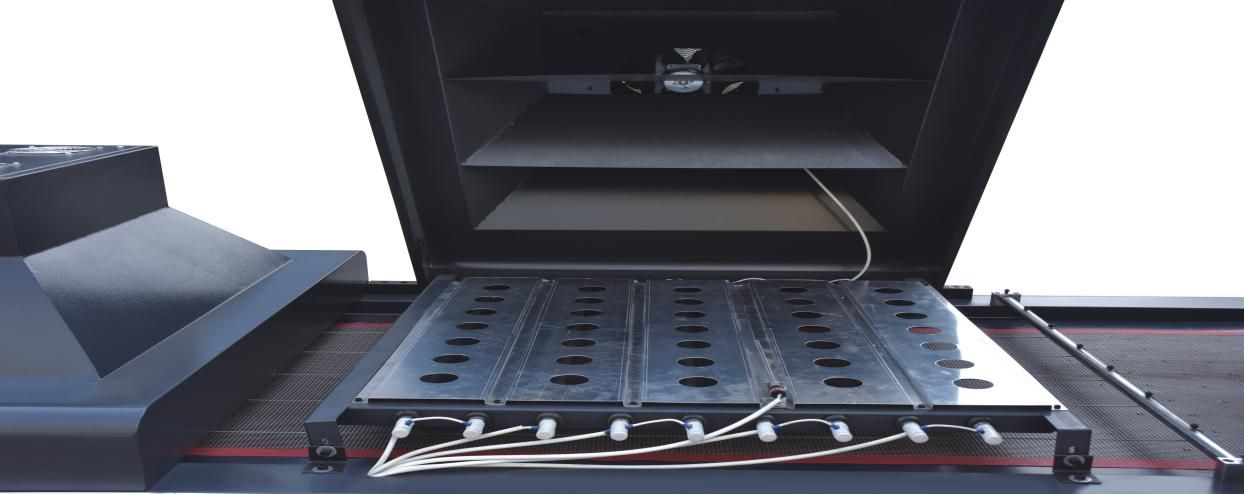

3. UV drying equipment(UV dryer + IR dryer)

- UV drying equipment adopts three UV mercury lamps, which can quickly solidify UV varnish.

- Equipped with full/half light conversion.

- Built-in automatic temperature control and electronic abnormal jumping.

- Water - based IR drying equipment, can dry water - based varnish.

4. Automatic paper stacker

- The paper stacker is equipped with an automatic paper loading platform.

- Photoelectric pneumatic two-sided paper leveller and strong paper flat and slow;Intermediate device to prevent the release of thick paper inertia;

Medium range to ensure smooth and neat paper receiving.

- Equipped with cooling fan and optional cooling air conditioning.

- Abnormal status indicator light and safety detection system to quickly inform the staff of abnormal status.

5. Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Specifications

| The main motor and reducer in the cutter: | Made by Taiwan,smooth transmission, precision, small vibration, low noise, durability |

| Air pressure controlling components: | The cylinder and solenoid valve are both use AirTAC |

| Optical detection: | Omron and Germany Schneider Electric (Omron) |

| Belt: | Italy SAMLA and Japan NIKO |

| Temperature control system: | |

| Chain | TYC |

| Bearing: | Japan NHK |

UV Spot Machine Spared parts

| NO. | Description | Specification | Qty | Unit | NO. | Description | Qty |

| 1 | Coating rubber roller | ¢137.6*1473 | 1 | pc | 10 | “-” Screw driver | 1 set |

| 2 | Plastic scraper | 2*38*1350 | 5 | pcs | 11 | open spanner | 1 set |

| 3 | Wedge woods | 4 | set | 12 | 6T spanner | 1 set | |

| 4 | Anchoring | M10*60 | 16 | pcs | 13 | Tool box | 1 set |

| 5 | Anchoring | M8*50 | 6 | pcs | 14 | Adjustable spanner | 1 set |

| 6 | Special Chain knot | 1” | 2 | pcs | 15 | Foot gasket | 1 set |

| 7 | Electrical cable ties | 5*200 | 10 | pcs | 16 | Conveyor shelf special foot gasket | 1 set |

| 8 | Suckers | 10 | pcs | 17 | Coating machine special foot gasket | 1 set | |

| 9 | “+”Screw driver | 1 | set |

Electric Configuration

| No. | Matrl name | Brand |

| 1 | Master switch | Schneider |

| 2 | Contactor | Schneider |

| 3 | Inverter circuit breaker | Schneider |

| 4 | Touchscreen | Taiwan Wei Lun |

| 5 | Inverter | Inovance |

| 6 | PLC | |

| 7 | Relays | Omron |

| 8 | Bottom switch | Schneider |

| 9 | Terminals | |

| 10 | Button operation | Taiwan Devadatta |

| 11 | Counter | Taiwan Yangming |

| 12 | Control paper align fiber | Omron |

| 13 | Proximity switchs | Omron |

| 14 | Control Circuit wires | Man Hing |

| No. | Matrl name | Brand |

| 1 | Master switch | Schneider |

| 2 | Contactor | Schneider |

| 3 | Inverter circuit breaker | Schneider |

| 4 | Touchscreen | Taiwan Wei Lun |

| 5 | Inverter | Inovance |

| 6 | PLC | |

| 7 | Relays | Omron |

| 8 | Bottom switch | Schneider |

| 9 | Terminals | |

| 10 | Button operation | Taiwan Devadatta |

| 11 | Counter | Taiwan Yangming |

| 12 | Control paper align fiber | Omron |

| 13 | Proximity switchs | Omron |

| 14 | Control Circuit wires | Man Hing |

Other Terms

| (1)Time of Delivery:25-35 days after receiving your advance payment |

| (2)Loading Port & Destination:From NINGBO,CHINA To your port |

| (3)Terms of Payment:30% T/T deposite,70% balance T/T payment before the shipment |

| (4)Quotation Valid time:30 days |

| (5)Warranty:One year free warranty start from waybill date. |