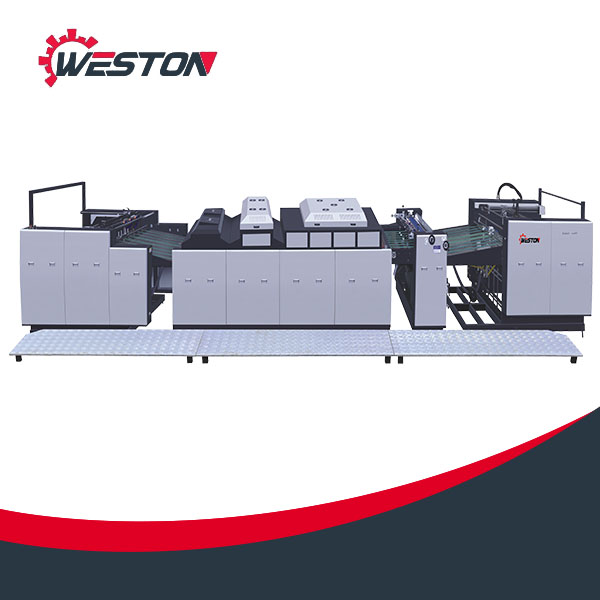

Specifications and Configurations of WST-BFP18 Auto Sheet-fed Square Bottom Paper Bag Machine (with Bottom Cardboard)

Product Specification

1.1.Product Introduction

This machine is designed to manufacture square bottom paper bags with top folding from sheet paper, and it is an ideal equipment for processing mid-to-high-end paper handbags. By implementing steps including paper feeding, line imposing, top folding, side gluing, tube forming, bag turnover, bottom forming, bottom cardboard inserting; this machine can effectively ensure high-quality paper bags as well as save labor costs. Equipped with advanced pre-heap paper feeder, this machine can realize non-stop feeding, thereby improving the production capacity. Special mechanical and electrical patented designs ensure that the machine can process various kinds of paper, thus being able to produce different excellent paper bags, which are especially suitable for food, clothing and luxuries industries.

Figure 1. Side View of WST-BPF18

Main Technical Parameter

| Model | WST-BFP18 |

| Paper Width | 550~1200mm |

| Paper Length | 310~630mm |

| Paper Thickness | 120~200g/m2 (Kraft Paper) 155~250 g/m2 (Art Paper+ Laminated Paper) 180~250 g/m2 (White cardboard + Laminated PP film) 150~300 g/m2 (Grey Paperboard + Laminated PP Film) |

| Bag Body Width | 180~430mm |

| Bag Body Height | 240~480mm |

| Bag Bottom Size | 80~180mm |

| Top Folding Depth | 25~50mm |

| Max. Production Speed | 40~60bags/min |

| Total Power | 15kw |

| Total Weight | Approx. 15000kg |

| Overall Dimension | L17300mm×W2600mm×H1700mm |

Note: the parameters above are not absolute; operator’s skills, temperature, moisture, material and size of paper, categories and quality of glue can affect production speed, rejection rate, and applicable range of machine.

Advantages

●Unconventional Bottom cardboard inserting function can effectively strengthen weight capacity of paper bags and reduce labor cost of customers. (Optional)

Figure 2. Advantage

●The machine can process various kinds of paper, including kraft paper, coated paper and laminated paper, etc.

Figure 3. Advantage

Finished Product Samples

Figure 4. Finished Product Samples

Technology Analysis

2.1.Full Forming Process of Common Paper Bag

Figure 5. Paper Patch Forming Process

Detailed Specification

3.1.Infeed Section

1)Separate sheet paper feeder is adopted for feeding sheet paper automatically.

2)The sheet paper alignment can be adjusted manually in the lateral pattern.

3.2.Top Folding Section

1)Bag mouth creasing first, then top folding.

2)Top folding adopts water glue spray pattern.

3.3.Creasing Section

1)Separate material in-feed and creasing frame is adopted in this section.

2)Two sets of in-feed nip rollers, each one consists of one steel roller and one rubber roller in a roll-to-toll pattern, and can adjust its impressing force by spring.

3)Disk-type creasing device (both of the up and down parts are adjustable) can be adjusted for making various bags with different widths.

3.4.Tube Forming Section

1)The process of making sheet paper into tube is supported by groups of rollers and conveyer belts, whose speed can be adjusted separately.

2)Side glue application adopts hot melt glue spray pattern.

3)The paper tube is transferred for side creasing by vacuum belt conveying system and impressing wheels.

4)Forming mould and groups of djustable multi-discs are used for side tucking; the width of the forming mould is consistent with that of the paper tube.

5)During side creasing the transmission is made by groups of rollers and conveyer belts, whose driving force is provided by main motor.

6)Finally the paper tube after side creasing is transferred through a track with width adjustable in chain-pulling pattern, so that it can be positioned precisely and suitable for bottom forming.

3.5.Turnover Section

1)The transmission is made by groups of rollers and conveyer belts, so the paper tube can turn over(the bottom face forward after turn over)

3.6.Bottom Opening Section

1)The whole machine is mainly controlled by inverter-fed motor.

2)Adjustable bottom creasing device is used to adjust the bag bottom size.

3)Only one creasing line on the bag bottom; no creasing line on the bag surface.

4)Drum grippers, center grippers and sucker work simultaneously for bottom opening; copper guide plate used to drive the bottom to be flat.

5)Multi-layers bottom forming drum, center grippers, second tuck clamps, and drum grippers are adjustable for ease of changeover.

6)Smooth conveyance from guide wheel and belt to bottom cardboard inserting unit.

3.7.Bottom Forming Section

1)The multi-type seamless glue spray is composed of servo motor and synchronous belt, connecting two water-sprayed glue gun systems or hot melt glue spraying system to evenly glue the bottom.

2)The dimension adjustment is controlled by PLC frequency conversion in the on-line electric box and controlled by the touch screen.

3)Guide plate and belt guide for bottom closing and recompaction molding

MAIN ELECTRIC CONFIGURATION LIST

| Description | Brand |

| Vacuum Pump | ORION |

| Main Motor | SIEMENS |

| Servo | PANASONIC |

| Air Cylinder | AIRTAC |

| Electric Element | SIEMENS |

| Inverter | PANASONIC |

| Glue Machine | NORDSON |

| Water Glue Machine | KEKI |

| Main Bearing | NSK/HRB |

| Relay | SCHNEIDER |

| Contactor | SCHNEIDER |

| Air Break Switch | SCHNEIDER |

| PLC | PANASONIC |

| Feeding Photo Sensor | PANASONIC |

| Touch Screen | MCSG |

| Auto Feeding Component | WEIJIE |

| Reducer Motor | WEMAT |

Others

4.1.Working Condition

| Parameters | |

| Power | 3 phases, 380V±10%, 50 Hz |

| Compressed Air |

pressure: 0.6 MPa volume: approx. 0.5 m3/min oil and humidity: ≯8 mg/m3 |

| Installation Height | max. altitude: 1500 m |

| Ambient Requirement |

relative moisture: max. 65% when 40℃ temperature range: 10~40℃ |

Note: due to the availability of imported components and special requirements of customized machines, with the precondition that the machine performance is not influenced, the machine specification may be changed without notice in advance.