YFMA-1080/1200A Fully Automatic High-speed Thermal Film Laminating machine With PET UV Dryer for Paper Bag

Specifications

If length of paper need be 1400mm, machine price extra add USD 3000

| Model | YFMA-1080A | YFMA-1200A |

| Max Paper Size | 1050x1050mm | 1200x1050mm |

| Min Paper Size | 290x290mm | 300x300mm |

| Paper Range | 100-500g/m2 | 100-500g/m2 |

| Laminating Speed | 0-80m/min | 0-80m/min |

| Gross Power | 30KW | 30KW |

| Total Weight | 8000kg | 8000kg |

| Overall Dimensions | 9000x2200x1900mm | 9000x2200x1900mm |

introduction

1: Pre-stacking mechanism to achieve non-stop paper feeding and delivery

2: Adopt high-speed offset press feeder (12000 sheets/hour) to ensure fast and stable operation

3: High level of intelligence, the whole machine is controlled by PLC and man-machine, and each part is connected with frequency conversion and servo to ensure speed synchronization and easy for one person to operate. The main motor adopts frequency conversion motor.

4: high-speed, high-efficiency and simple operation

5: The main drive of the whole machine adopts synchronous belt drive, which makes the drive stable and accurate, and at the same time ensures the accuracy, and greatly improves the stability and service life of the machine. (first adopted among peers)

It is a high-speed pre-coating machine launched by our company, which is suitable for laminating processes such as posters, books, brochures, posters, color boxes, color box packaging, and handbags.

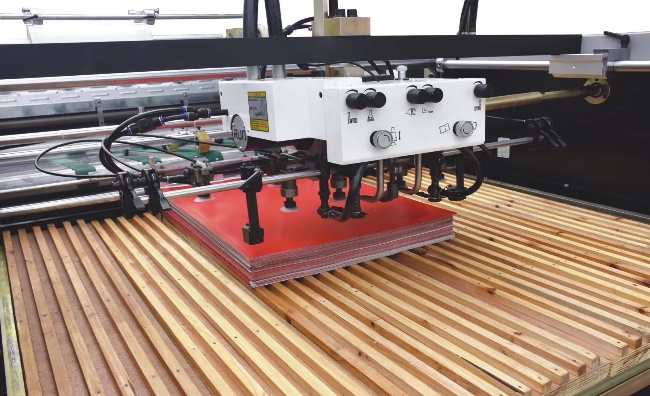

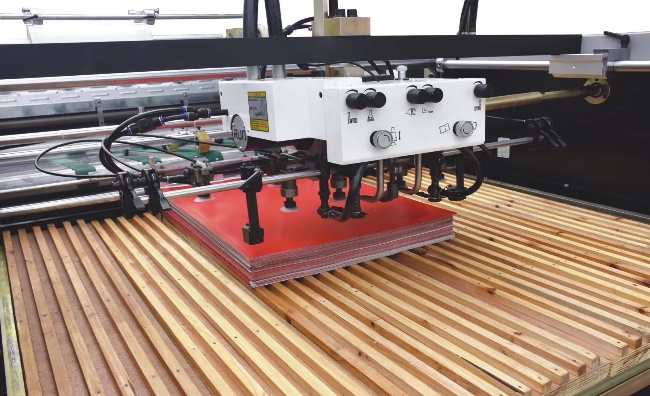

Auto Feeder

Detailed function configuration introduction

1. Automatic paper feeding system and features Automatic paper feeding system.

The paper feeder is an important part of the coating machine. The function of the paper feeder is to automatically, accurately, steadily and periodically separate the sheets one by one, and continuously send them to the regular positioning parts.

The paper feeding method of this machine is continuous paper feeding, which has the advantages of high automation, compact structure, good performance, convenient operation, accurate paper feeding and high precision. The main components of the paper feeder are the paper feed bridge, the paper feed head, the stacking table, the lifting system and the transmission system.

(1) Adopt oil-free vacuum air pump suction system;

(2) High-speed offset printing feeder (12,000 sheets/hour) ensures high-speed and stable operation!

(3) Stepless frequency conversion speed regulation paper feeding

(4) The paper feeding table of the production line is positioned and conveyed by vacuum suction to ensure smooth, tidy and stable conveying.

(5) The upper and lower limit protection devices of the feeding table; manual rapid lifting;

(7) The paper feeding table automatically replenishes the paper feeding system;

(8) Attached double sheet controller: double or multiple sheet feeding detection and shutdown system: use the induction of the safety voltage detector to detect double or multiple sheets of paper;

(9) Servo technology, PLC control and human-computer interaction system centralized control, the printing paper stacking error is ±2mm;

(10) Front gauge/pull gauge positioning system

This machine is equipped with a paper preload stacker, Servo controlled feeder and a photoelectric sensor to ensure that paper is continuously feed into the machine.

Laminating features

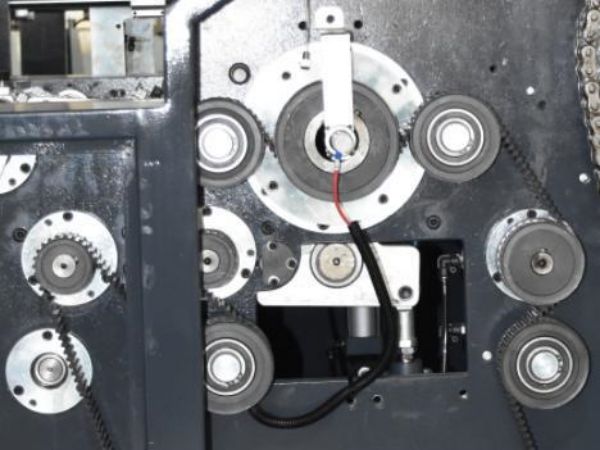

(1) The whole machine adopts high-precision synchronous belt and some imported chains for transmission;

(2) 320mm composite heating roller, matching electromagnetic variable power heating system;

(3) 300mm imported silicone pressure roller, with good temperature and pressure resistance and non-stick performance;

(4) Electromagnetic heating

(5) film straigt roller

(6) External temperature measurement temperature meter outside

(7) automatic hydraulic automatic pressure

(8) Paper lacking and breaking system

(9) Configure powder removal to make the surface effect better

(10) Anti-smudge magnet safety device to protect the iron roller!

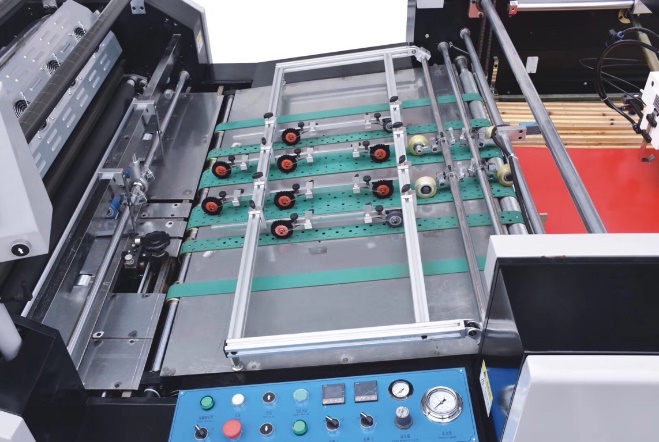

Suction Device And Side Lay Regulator

Suction device guarantees stability and smooth of paper sending.

The Servo controller and side lay mechanism guarantees precise paper alignment at all times.

Electromagnetic Heater

Equipped with advanced electromagnetic heater. Fast pre-heating. Energy saying. Environment protection.

Human Computer Interface

User-friendly interface system with a color touch screen simplifies the operation process. The operator can easily and automatically control paper sizes, overlapping and machine’s speed.

3.Slitting system and featuresSeparation system

(1): back punching back perforatingsystem

(2): high speed rotation knife

(3): Anti-curve device to flatten the paper anti-curvesystem

(4): pneumatic perforating cutting system

(5): Slotting the slitting rubber roller, slot for the separating roller

(6): Adopt the centralized control system of the whole machine to achieve precise pneumatic breaking

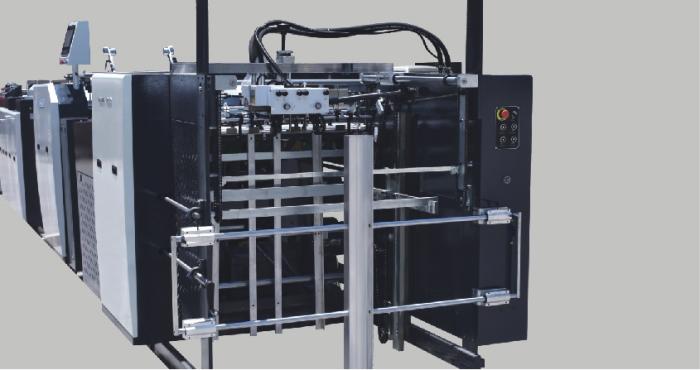

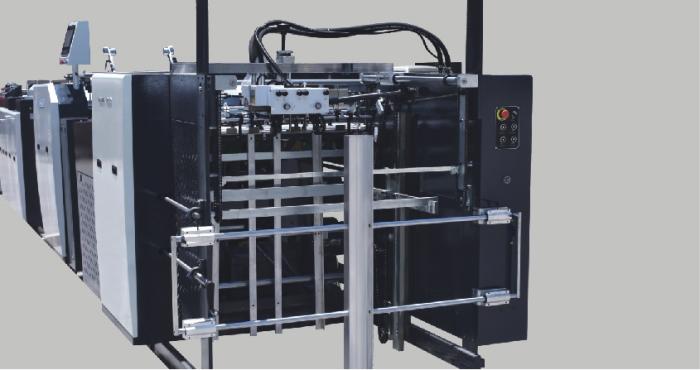

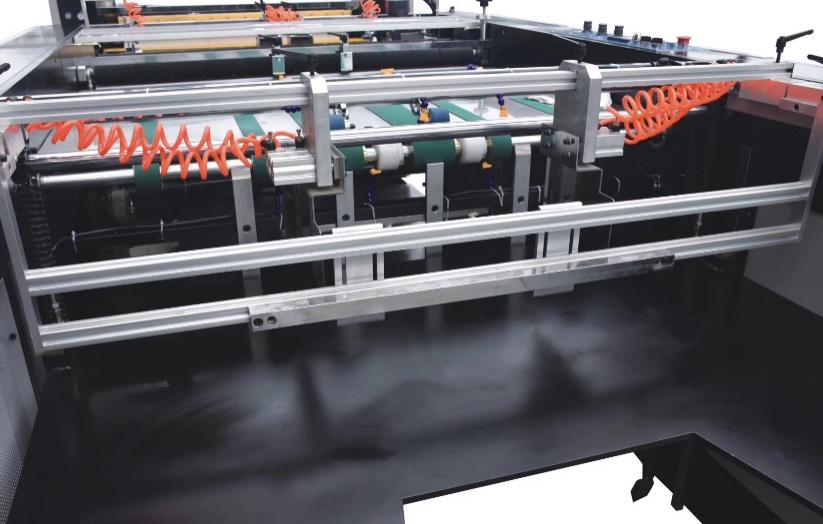

Automatic stacker

The pneumatic stacker receive the paper, keeping them in order, while rapidly counting every sheet. Automatic paper stacker features

The automatic paper delivery machine is equipped with a fan-cooled paper pressing structure, which can perfectly deliver the paper under the high-speed operation of the machine, ensuring that the paper is delivered neatly.

(1) The belt has low-noise delivery, and the upper and lower rails are designed to ensure smooth and smooth delivery;

(2) Thin paper corrugated paper delivery system, vacuum suction paper stabilizer device to keep the paper stable;

(3) The delivery table can be raised and lowered manually;

(4) The upper and lower limit protection devices of the delivery table;

(5) The automatic lowering device of the delivery table, and the delivery limit paper stop and alarm system;

(6) Automatic paper accumulation count;

(7) Match the paper jam detection system to realize intelligent deceleration

(8) Using high-speed pneumatic photoelectric single-sheet paper-taking system, the paper is accurate and neat;

Configuration

| NO. | Name | MODEL | QTY | REMARKS |

| 1 | PLC | 40MT | 1 | Inovance |

| 2 | touch screen | 6070T | 1 | Weinview |

| 3 | Servo drive | IS5-9S2R8/400W | 1 | Inovance |

| 4 | frequency changer | 2.2KW | 1 | PNEUMATIC |

| frequency changer | 4KW | 1 | HYDRAULIC PREASURE | |

| 5 | miniature circuit breaker | DZ60-47/C32A | 1 | SCHNEIDER |

| 6 | miniature circuit breaker | DZ60-47/C10 | 2 | SCHNEIDER |

| 7 | alternating current contactor | 1210/220V | 6 | SCHNEIDER |

| 8 | alternating current contactor | 3210/220V | 1 | SCHNEIDER |

| 9 | intermediate relay | MY2N-J | 9 | OMRON |

| 10 | Solid state contactor | J25S25 | 2 | CHINA |

| 11 | Voltage heating module | 3PH60DA-H | 1 | WUXI |

| 12 | limit switch | YBLX-ME/8108 | 2 | SCHNEIDER |

| 13 | Pressure limit switch | ME-8111 | 1 | SCHNEIDER |

| 14 | Reflection type photoelectric switch | HE18-R2N/24V | 1 | OMRON |

| 15 | Square photoelectric switch type | E3Z | 1 | OMRON |

| 16 | photoelectric switch | DS30 | 1 | OMRON |

| 17 | proximity switch | BB-U202N/24V | 1 | OMRON |

| 18 | pilot lamp | XB2 | 1 | SCHNEIDER |

| 19 | Transfer switch | ZB2-BDZC | 4 | SCHNEIDER |

| 20 | stop switch | BS54C | 3 | SCHNEIDER |

| 21 | button switch | ZB2(Green、White、Red) | 2(Green)+1(white)+1(red) | SCHNEIDER |

| 22 | encoder | E6BZ-CW26C/1000R/24V | 1 | OMRON |

| 23 | Power Module | S-35-24 | 1 | TAIWANG |

| 24 | temperature-sensing wire | 1-model | 1 | OMRON |

| 25 | thermograph | MXTG-6501 | 1 | OMRON |

| 26 | Switch contact | Normal open:ZBS-BZ101 | 10 | OMRON |

factory

Machine at factory

Machine at customer workshop

Package Photo

Other Terms

| (1)Time of Delivery:15-35 days after receiving your advance payment |

| (2)Loading Port & Destination:From NINGBO,CHINA To your port |

| (3)Terms of Payment:30% T/T deposite,70% balance T/T payment before the shipment |

| (4)Quotation Valid time:30 days |

| (5)Warranty:One year free warranty start from waybill date. |