YFMA-590/800A Automatic Thermal Laminating Machine with embossing feature for photo book

Technical Date

| Model | YFMA-800A | YFMA-590A |

| Max Paper Size | 760x1020mm | 590*780mm |

| Min Paper Size | 240x270mm | 240x200mm |

| Paper Thickness | 100-500g/m2 | 100-500g/m2 |

| Laminating Speed | 60-80m/min | 0-80m/min |

| With Embossing Speed | 10-30m/min | 10-30m/min |

| Temperature: | 80-110。C | 80-110。C |

| Gross Power | 25kw | 18kw |

| Total Weight | 3800kg | 3600kg |

| Overall Dimensions | 5600x1650x1650mm | 5000x1350x1650mm |

Features

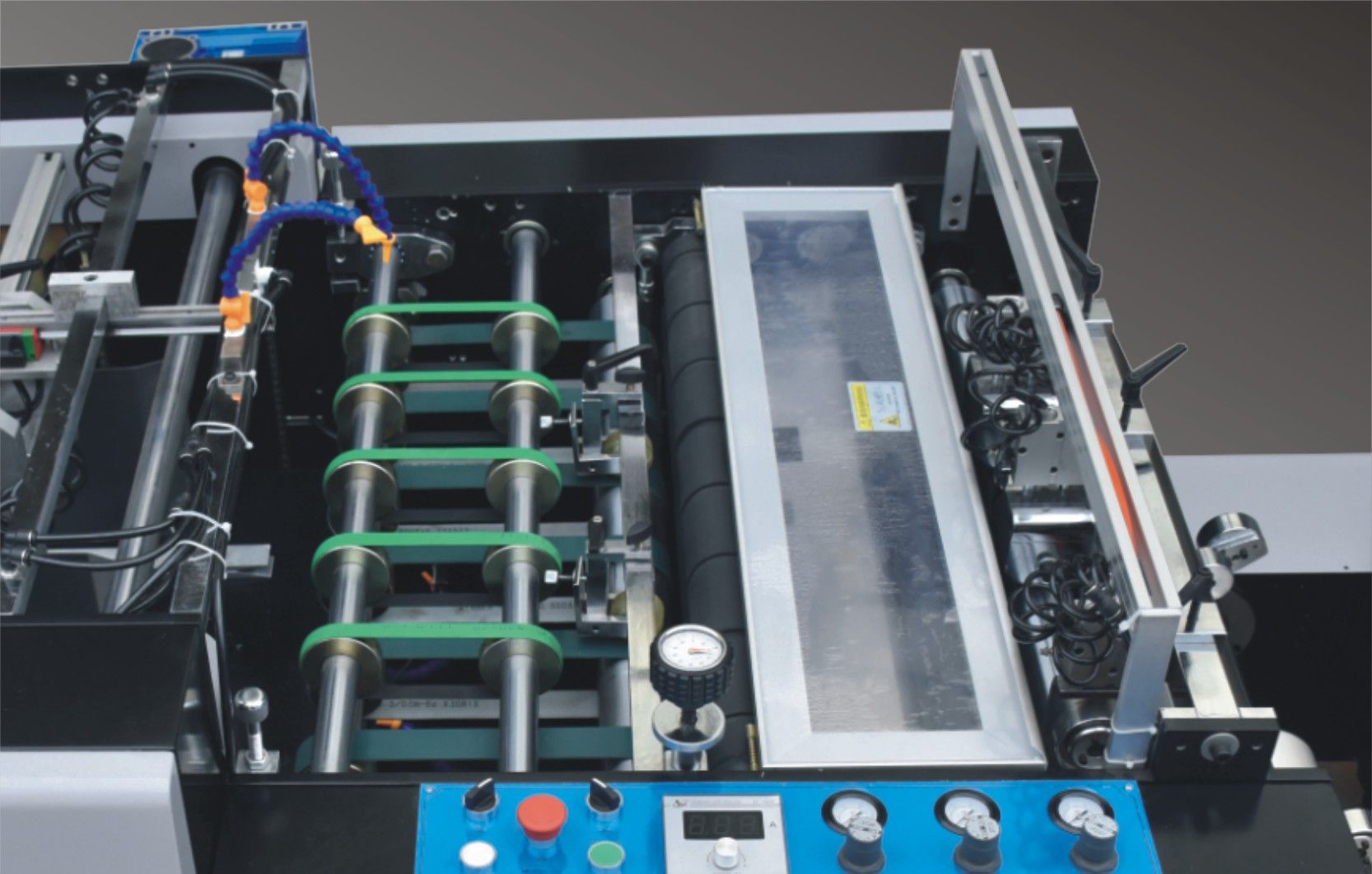

Laminating

(1) The whole machine adopts high-precision synchronous belt and some imported chains for transmission;

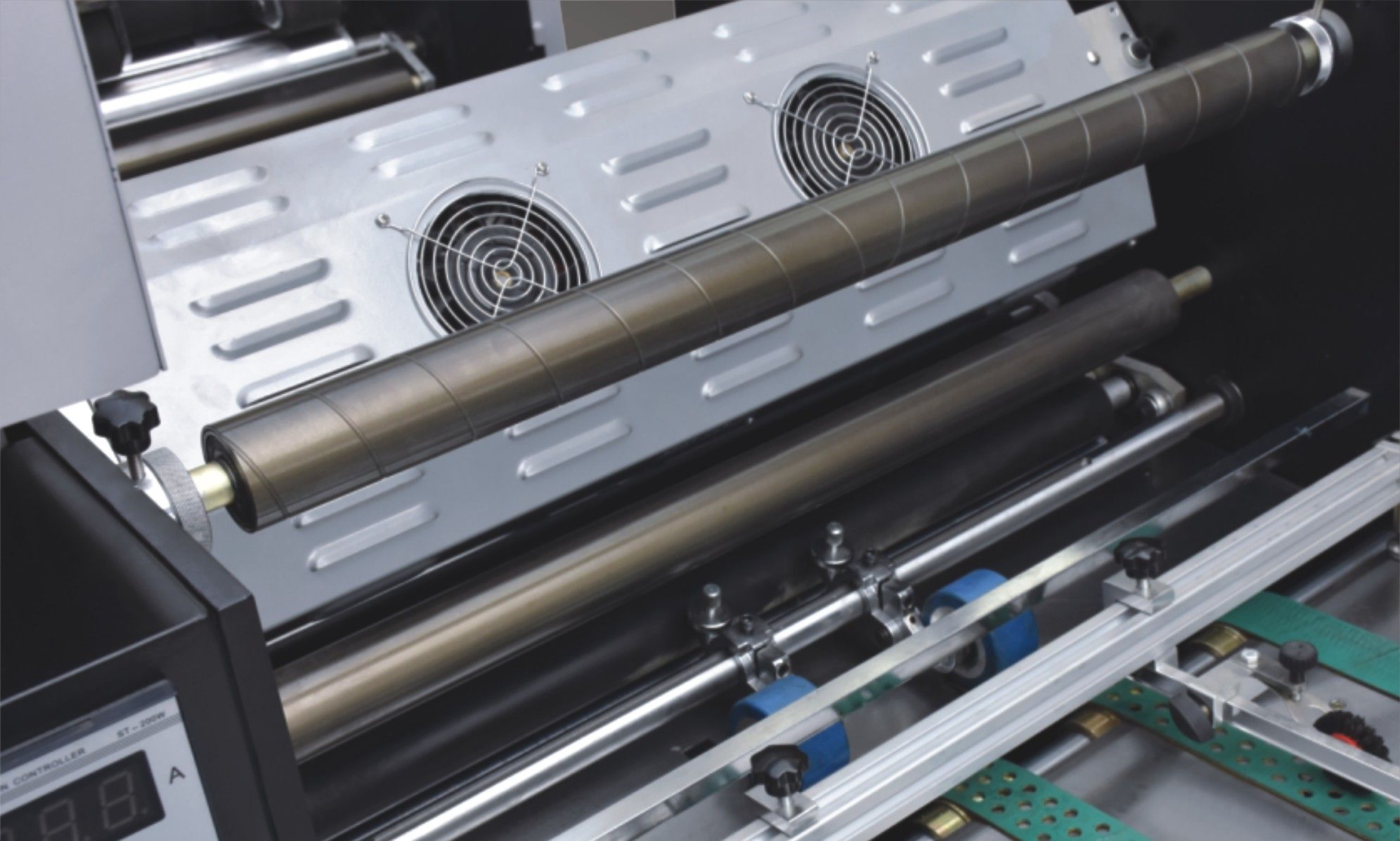

(2) 320mm composite heating roller, matching electromagnetic variable power heating system;

(3) 300mm imported silicone pressure roller, with good temperature and pressure resistance and non-stick performance;

(4) Electromagnetic heating

(5) film straigt roller

(6) External temperature measurement temperature meteroutside

(7) automatic hydraulic automaticpressure

(8) Paper lacking and breaking system

(9) Anti-smudge magnet safety device to protect the iron roller.

Separation system

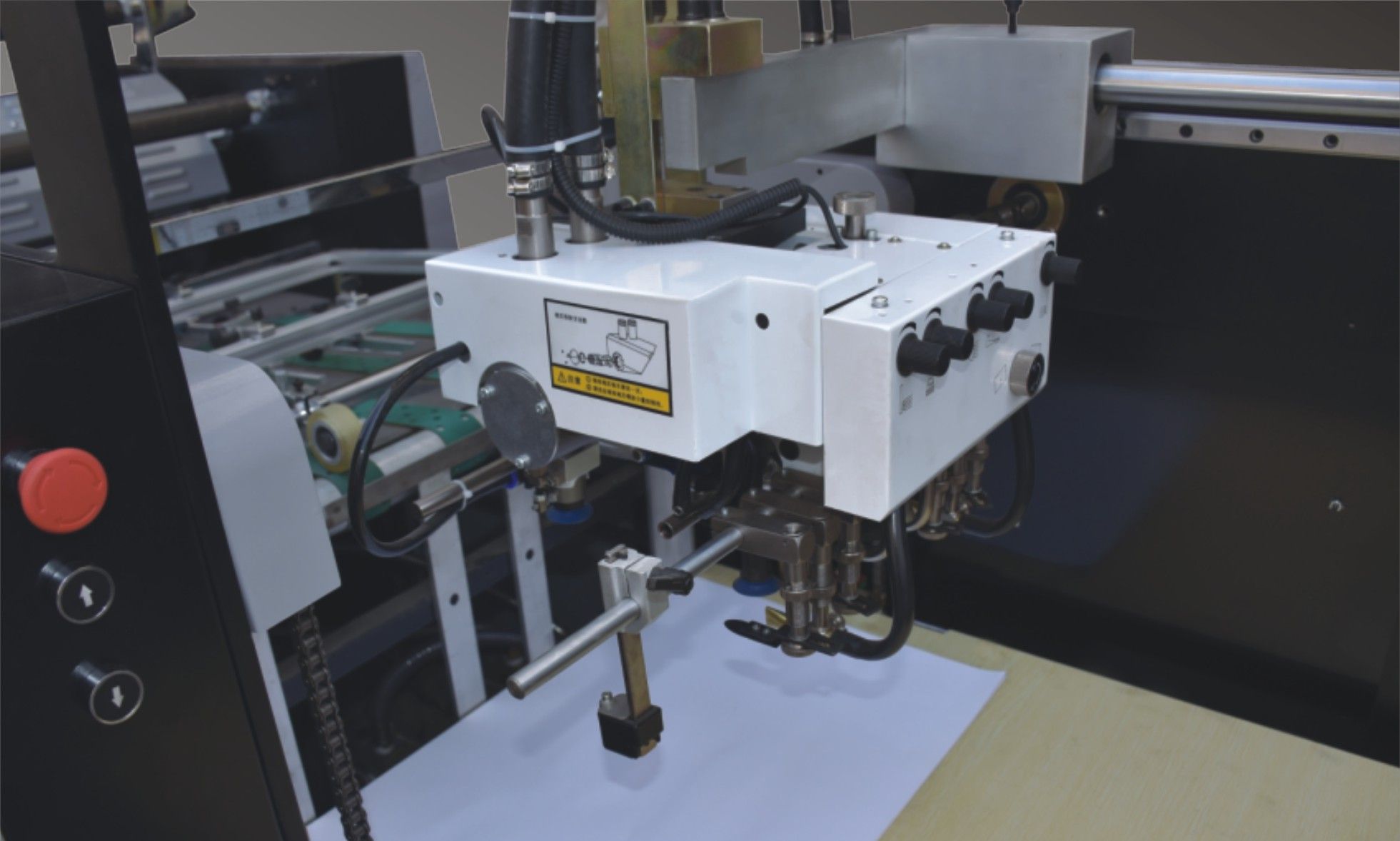

(1) back punching back perforatingsystem

(2)Anti-curve device to flatten the paper anti-curvesystem

(3)Pneumatic perforating cutting system

(4)Slotting the slitting roller, slot for the separating roller

(5)Adopt the centralized control system of the whole machine to achieve precise pneumatic breaking

(6)Magnetic powder clutch control

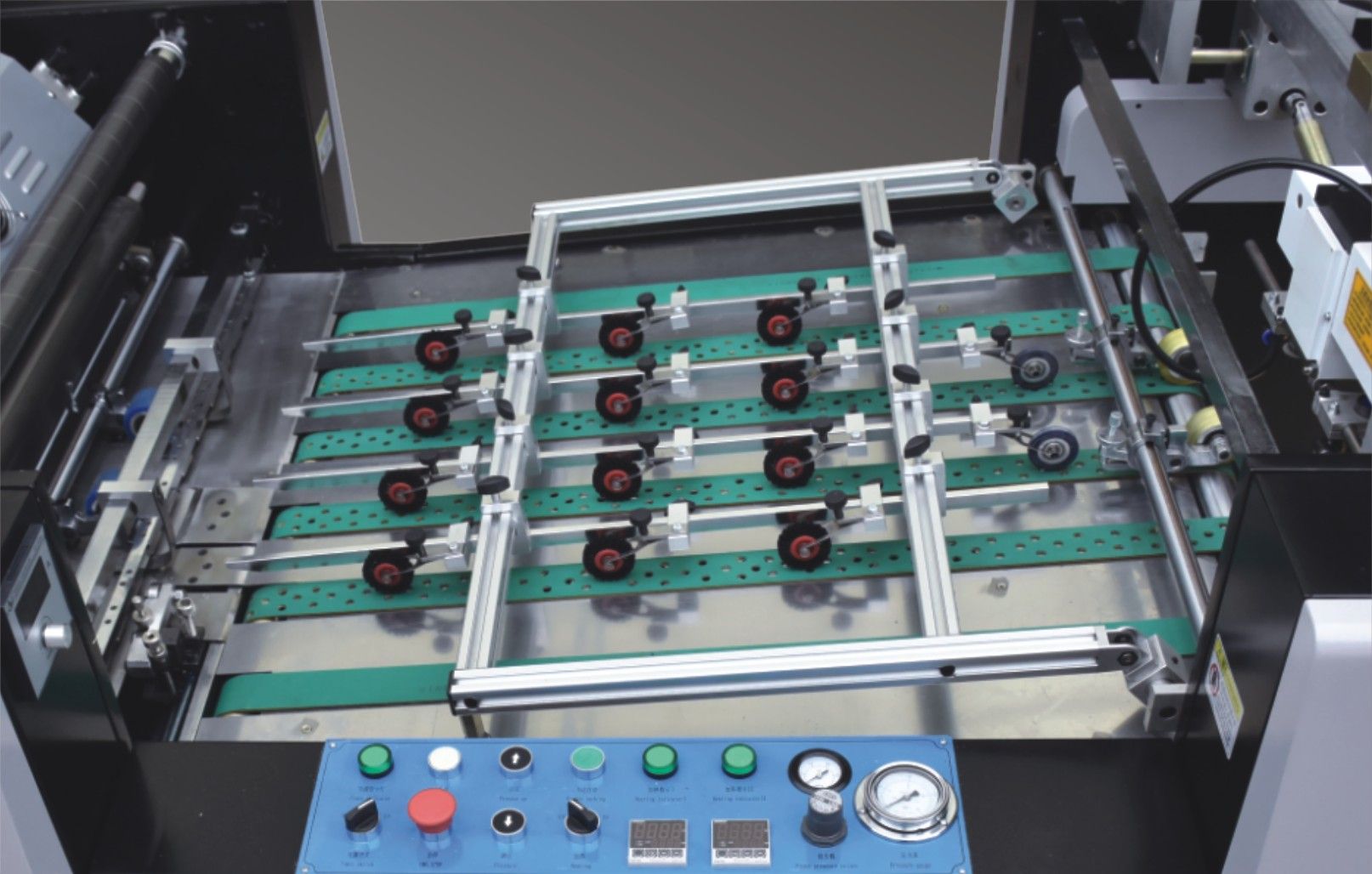

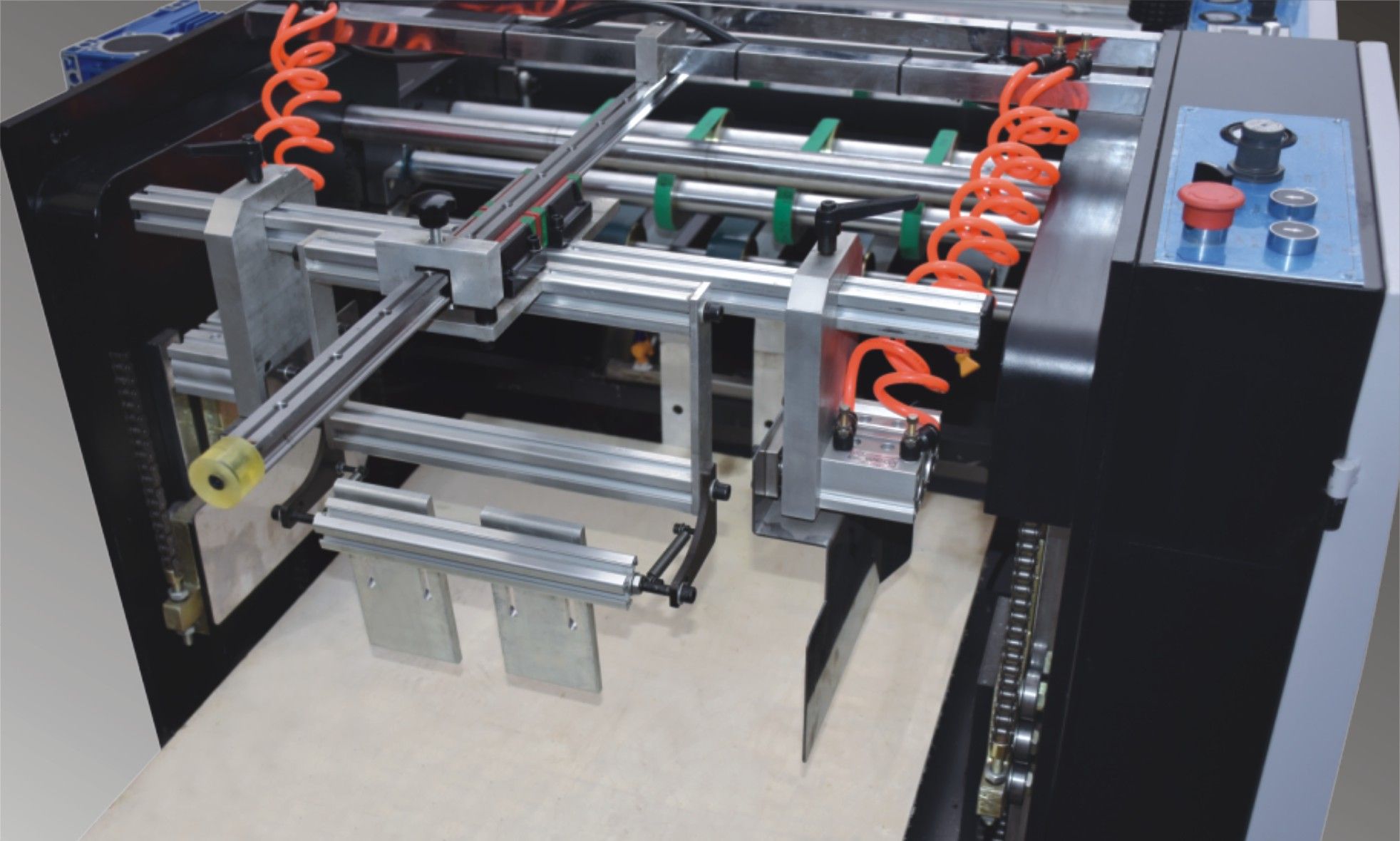

Automatic paper stacker

(1)Thin paper corrugated paper delivery system, vacuum suction paper stabilizer device to keep the paper stable;

(2) The delivery table can be raised and lowered manually;

(3) The upper and lower limit protection devices of the delivery table;

(4) The automatic lowering device of the delivery table, and the delivery limit paper stop and alarm system;

(5) Automatic paper accumulation count;

(6) Using high-speed pneumatic photoelectric single-sheet paper-taking system, the paper is accurate and neat;

YFMA series automatic laminating machine is a compound device, it is mainly equipped with transportation system, laminating system and cutting system. The electrical device is controlled by PLC, heating roller use the electromagnetic heating roller to ensure the accuracy of laminating temperature. The whole machine has compact structure, automatic and humanity operation. It is the good choice for the large and medium scale enterprise.

Automatic paper feeder adopts oil-free vacuum pump to feed paper automatically.

Automatic paper feeding system is equipped with no paper protector and paper break protector, which are controlled by photoelectric and mechanical systems. When no paper or paper break occurs, the machine will stop automatically for self-protection.

Conveying table is furnished with air aspirator and front lay etc. to guarantee paper conveying and overlap stable and regular. Front lay can guarantee the accuracy of paper overlapping.+_2MM.

High precision of chrome plated heating roller is equipped with electromagnetic heating system, which has excellent performance to temperature control. The laminating temperature is adjustable upon applications.

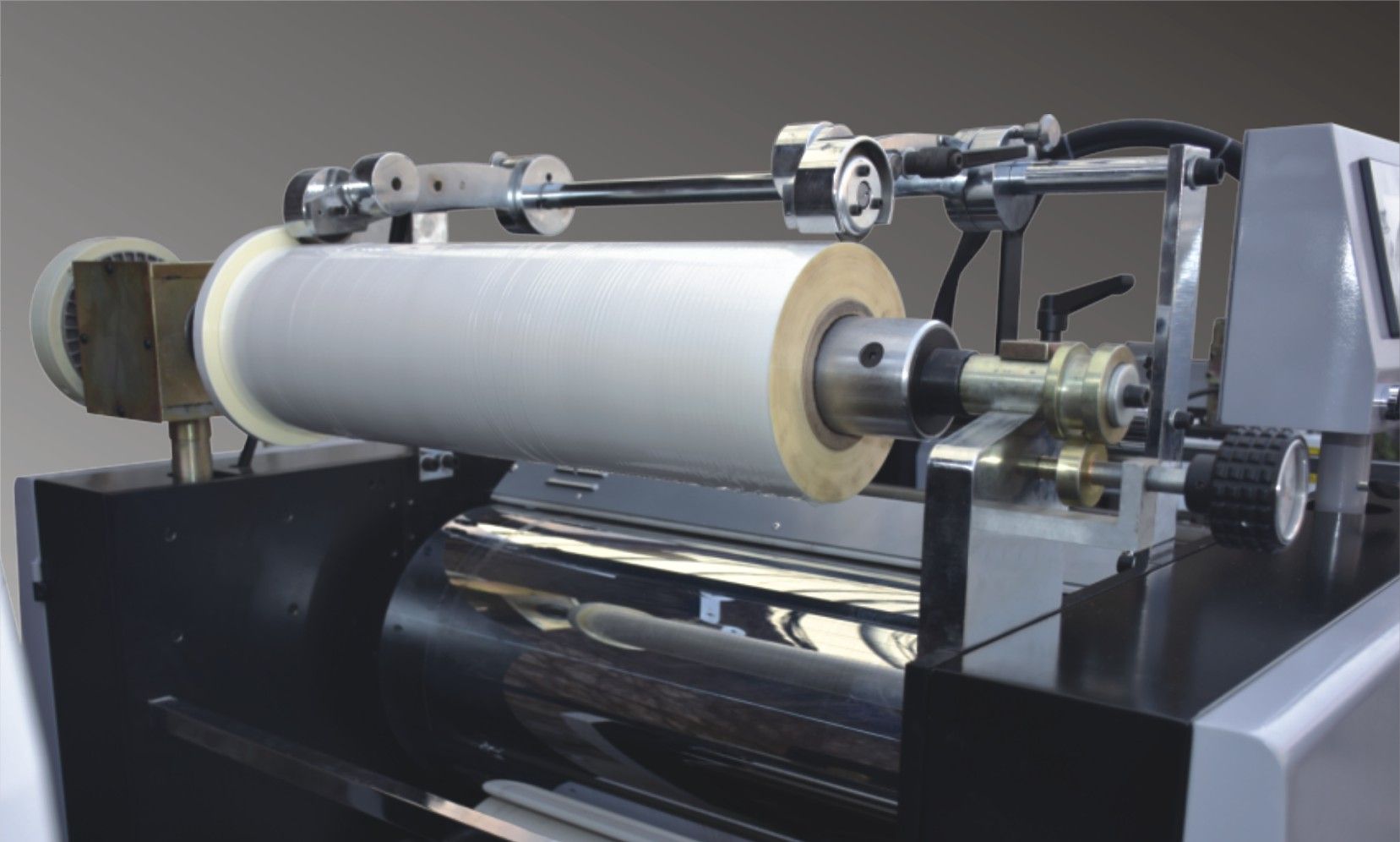

Pneumatic pressuring system provides automatically steady pressure to guarantee good quality . The pressure is adjustable upon applications.Air expansion shaft releases film, and precision film release, and also makes the loading and unloading of film roll more convenient. The combination of air expansion shaft and braking device can adjust film release tension and speed.

Film cutter cuts film width to make it meet paper size. The cut film is left on the film release spindle. Film perforating wheel perforates film edge for the automatic cut of laminated paper.

Anti-curvature device: When going through the anti-curvature device, the laminated paper shall be leveled at once and won't curve again after cut. Pneumatic cutting system realizes automatic paper cut.

Man-machine interface system + color touch screen simplifies the machine operation. As long as the operator inputs paper size, overlap length and working speed etc,. the machine can realize completely automated operation. The working status of the machine can be checked at any time on touch screen.

Auto paper collector equipped with pat device stacks and tidies up cut paper. Patting frequency of pat device is adjustable.

Embossing & Machine at Customer workshop

Packaging Photo

Packaging

3 Packing , size: 1.L*W*H :3310*1610*1920mm 2.L*W*H :2100*1550*1700mm L*W*H :1500*450*1100mm

20 FT CONTAINER REQUEIED, Remain space can load two ton of film or other goods.

Other Terms

| (1)Time of Delivery:30-40 days after receiving your advance payment |

| (2)Loading Port & Destination:From NINGBO,CHINA To your port |

| (3)Terms of Payment:30% T/T deposite,70% balance T/T payment before the shipment |

| (4)Quotation Valid time:30 days |

| (5)Warranty:One year free warranty start from waybill date. |

Other Terms

| NO. | Name | MODEL | QTY | REMARKS |

| 1 | PLC | 40MT | 1 | Inovance |

| 2 | touch screen | 6070T | 1 | Weinview |

| 3 | Servo drive | IS5-9S2R8/400W | 1 | Inovance |

| 4 | frequency changer | 2.2KW | 1 | PNEUMATIC |

| frequency changer | 4KW | 1 | HYDRAULIC PREASURE | |

| 5 | miniature circuit breaker | DZ60-47/C32A | 1 | SCHNEIDER |

| 6 | miniature circuit breaker | DZ60-47/C10 | 2 | SCHNEIDER |

| 7 | alternating current contactor | 1210/220V | 6 | SCHNEIDER |

| 8 | alternating current contactor | 3210/220V | 1 | SCHNEIDER |

| 9 | intermediate relay | MY2N-J | 9 | OMRON |

| 10 | Solid state contactor | J25S25 | 2 | CHINA |

| 11 | Voltage heating module | 3PH60DA-H | 1 | WUXI |

| 12 | limit switch | YBLX-ME/8108 | 2 | SCHNEIDER |

| 13 | Pressure limit switch | ME-8111 | 1 | SCHNEIDER |

| 14 | Reflection type photoelectric switch | HE18-R2N/24V | 1 | OMRON |

| 15 | Square photoelectric switch type | E3Z | 1 | OMRON |

| 16 | photoelectric switch | DS30 | 1 | OMRON |

| 17 | proximity switch | BB-U202N/24V | 1 | OMRON |

| 18 | pilot lamp | XB2 | 1 | SCHNEIDER |

| 19 | Transfer switch | ZB2-BDZC | 4 | SCHNEIDER |

| 20 | stop switch | BS54C | 3 | SCHNEIDER |

| 21 | button switch | ZB2(Green, White, Red) | 2(Green)+1(white)+1(red) | SCHNEIDER |

| 22 | encoder | E6BZ-CW26C/1000R/24V | 1 | OMRON |

| 23 | Power Module | S-35-24 | 1 | TAIWANG |

| 24 | temperature-sensing wire | 1-model | 1 | OMRON |

| 25 | thermograph | MXTG-6501 | 1 | OMRON |

| 26 | Switch contact | Normal open:ZBS-BZ101 | 10 | OMRON |