YFMA-850S Automatic Vertical Multi function Laminating machine

Main Specifications

| Model | YFMA-850S |

| Speed | 10-110M/min ( 12000PCS/h) |

| Max paper size | W850×L1050MM |

| Min Paper size | W290×L300MM |

| paper weight | 80-500g/㎡ |

| Feeding paper pallet height | 1200 mm |

| Power | 20-25KW/hours |

| Total Power | 60kw ( 380V AC3φ 50HZ) |

| L 8600 × W 1800 × H 2000 mm |

The functions and character

The whole machine wall panel adopts the machining center for deep processing to ensure stable product quality, long service life and low noise. Parts are completed at one time by CNC lathes and machining centers to ensure product standardization, integration, and unified management of acceptance and storage.

This machine is an intelligent vertical lamination equipment with a high degree of automation, and is highly efficient and energy-saving (power consumption is about 15 degrees per hour). The machine has complete functions, adopts humanized design, adopts PLC centralized control, and automatically detects faults And automatically make corresponding treatment, the drying system adopts a hot air circulation system, combined with an active follow-up drying and heating device, which improves the drying efficiency of acceleration and deceleration, and greatly improves the control performance of the whole machine. With the human-machine interface, the operation is more intelligent and humanized. It consists of high-speed paper feeder, powder remover, lamination and coating device, finished product breaking and paper delivery machine.

The main drive of the whole machine adopts synchronous belt drive, which makes the drive stable and precise, and at the same time ensures the accuracy, and greatly improves the stability and service life of the machine. (first adopted among peers)

The whole machine has an electric energy meter to monitor the voltage, current and power in real time, and has the power consumption and output statistics of each shift.

Configuration Instructions

1. High-speed paper feeder

- Maximum paper height: 1100mm;

- Equipped with longitudinal and lateral positioning mechanisms;

- Adopt servo technology, PLC control and human-computer interaction system centralized control;

- The position of the paper is controlled within ±2mm;

- Oil-free vacuum pump;

-Paper pile detection mechanism, paper shortage detection mechanism and other series of sensing detection mechanisms.

2. Laminating host

-The whole machine adopts high-precision synchronous belt and some imported chains for transmission;

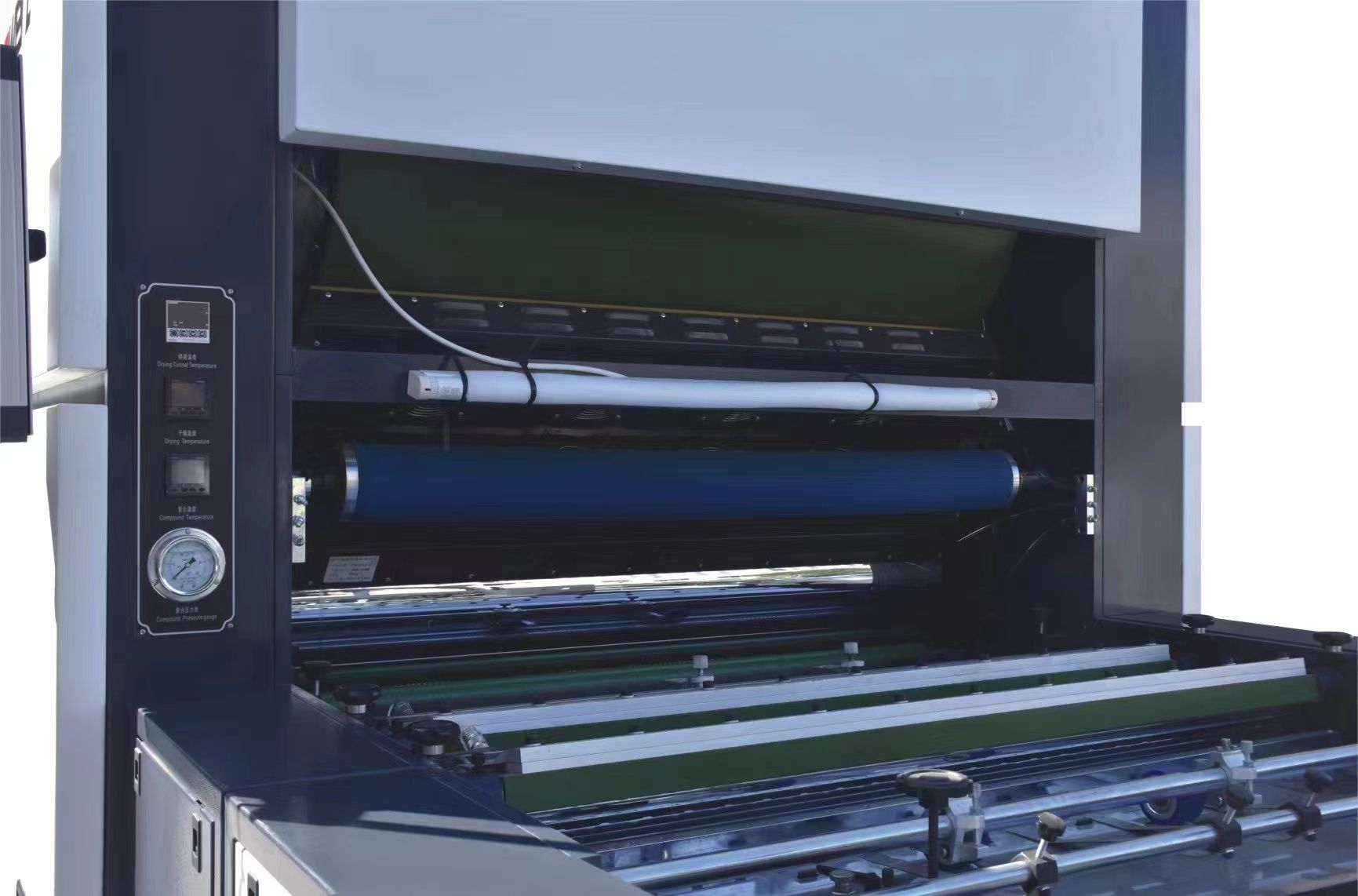

-380mm composite heating roller, matching electromagnetic variable power heating system;

-320mm imported silicone pressure roller, with good temperature and pressure resistance and non-stick performance;

-800mm drying large heat roller, coated with industrial non-stick material Teflon;

-The drying system adopts a hot air circulation system, combined with an active follow-up drying and heating device;

3. Slitting system

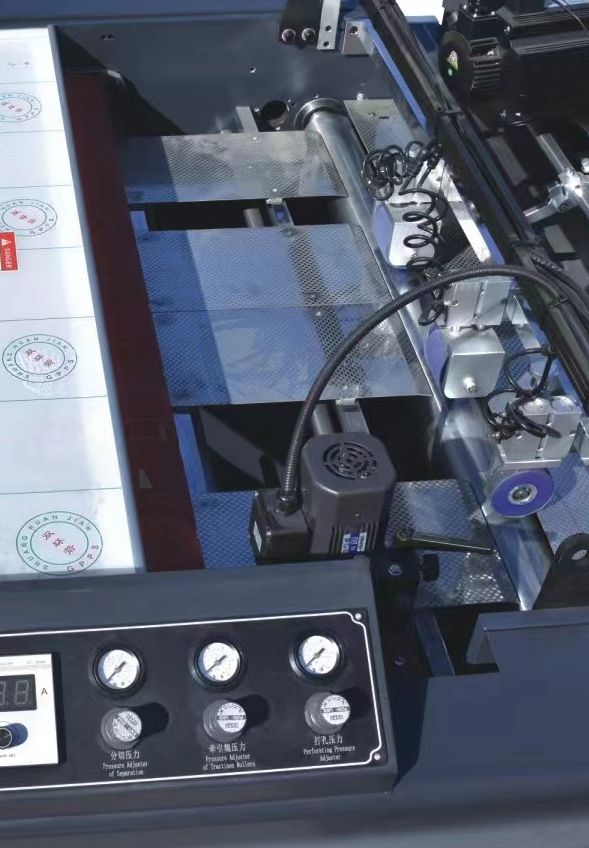

- Adopt active follow-up cutting technology for slitting;

- Comes with a disc knife cutout

- Using the centralized control system of the whole machine to achieve precise pneumatic breaking

4. Automatic take-up machine

-Auxiliary suction and buffer system;

- Loaded with wave pressure device, matched with pneumatic automatic paper flapping;

- Loading automatic reject device;

- Match the paper jam detection system to realize intelligent deceleration;

-(Optional) Servo intelligent board changing without manual care. +

Electrical configuration list

1.Low voltage circuit breaker: French Schneider

2.2. Intermediate relay: French Schneider

3. Programmable controller: Inovance Technology

4. Inverter: Inovance Technology

5. Rotary encoder: German SICK

6. Switching power supply: Taiwan Mingwei

7. AC contactor: French Schneider

8. Button: French Schneider

9. Touch screen: FLEXEM

10. Pneumatic components: AirTAC Taiwan

11. Photoelectric switch: Japanese Panasonic

12. Motor: China Dedong Transmission

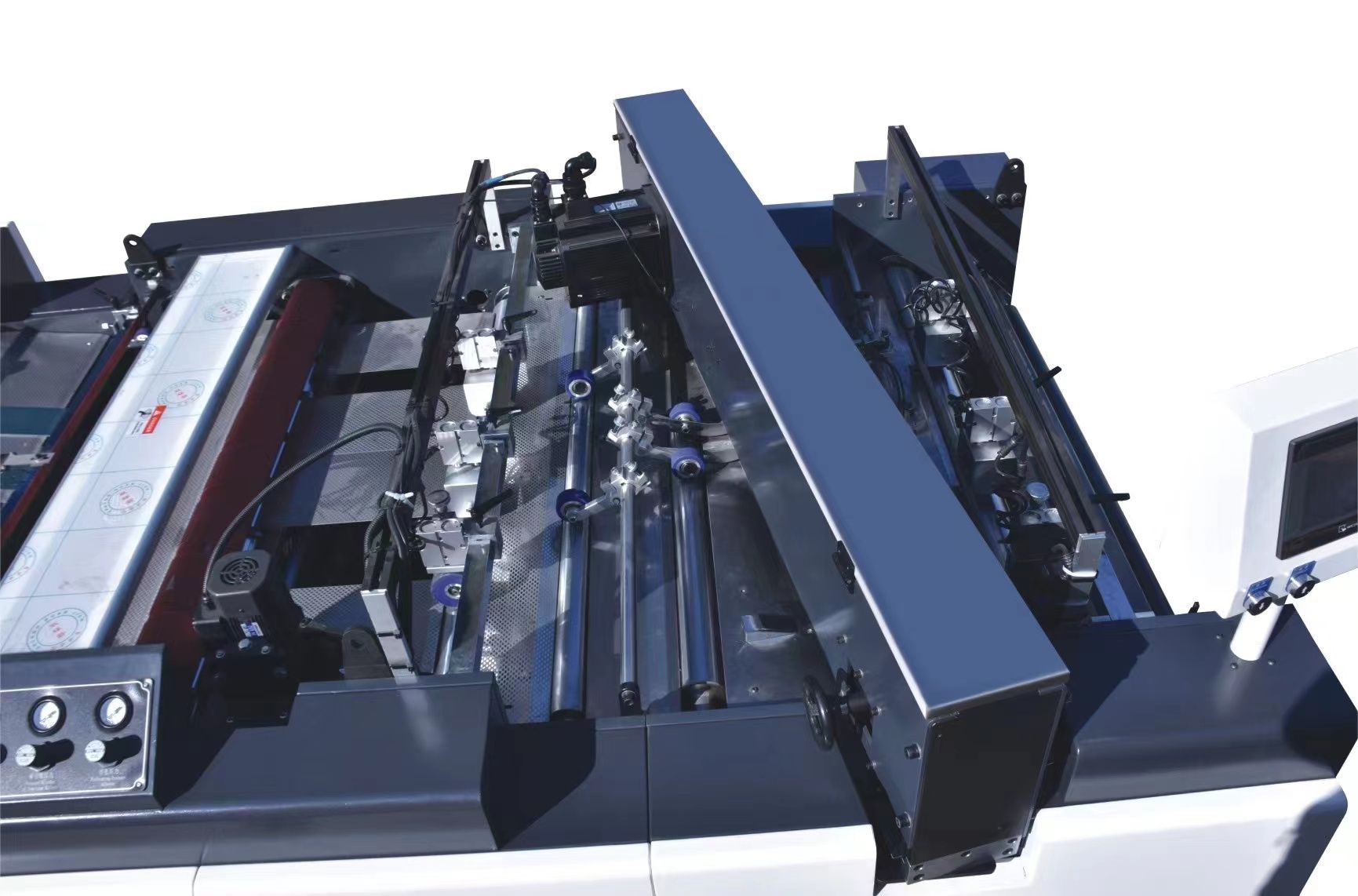

Configuration Center Photos

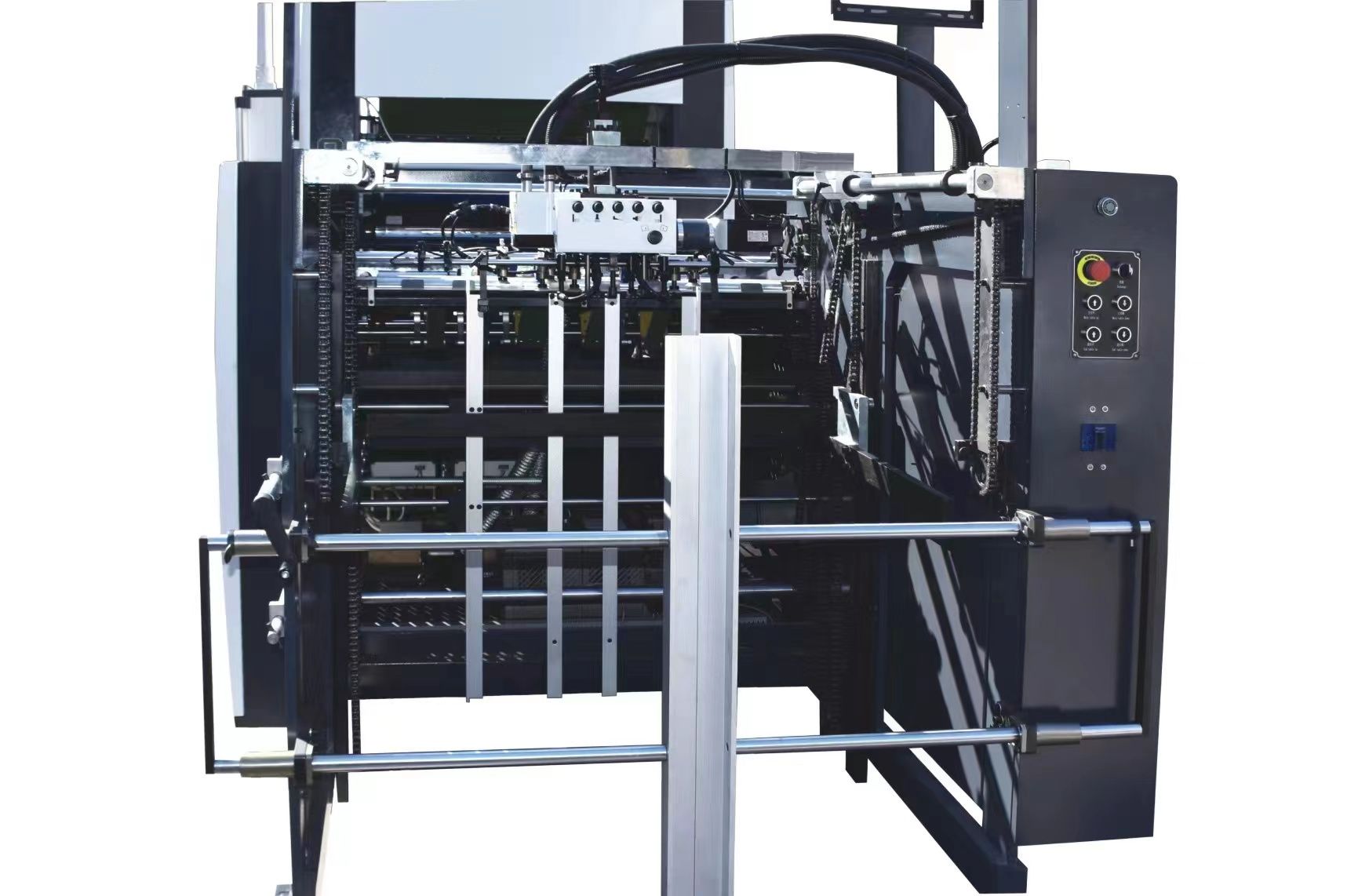

High Speed Automatic Paper Feeding System

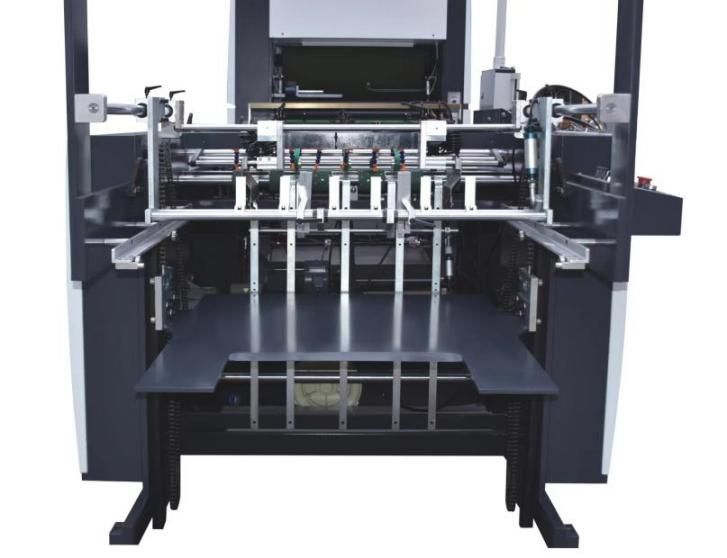

High Precision Lays

Power Cleaning Unit

Electromagnetic heating system and infrared temperature control system

Lamination and coating mechanism

Disc flying knife mechanism

Slitting and wave pressure mechanism

Collecting System

Feida transmission system

Chain Knife (Optional)

Other Terms

| (1)Time of Delivery:30-45 days after receiving your advance payment |

| (2)Loading Port & Destination:From NINGBO,CHINA To your port |

| (3)Terms of Payment:30% T/T deposite,70% balance T/T payment before the shipment |

| (4)Quotation Valid time:30 days |

| (5)Warranty:One year free warranty. |